Miter Saw vs Table Saw: Which Should You Use? (Ultimate Guide)

Miter saws and table saws are two popular saws that woodworkers use to make a variety of cuts, but which is better overall and when should you use each one?

In this post, I’ll explain the differences between miter saws and table saws, the types of cuts they can make, when you should use each, and much more.

Ready to learn the differences between a miter saw vs table saw? Let’s dig in!

- A miter saw is great for making crosscuts, miter cuts, and bevel cuts, but a table saw can make all these cuts and more, including dado cuts, rabbet cuts, and rip cuts.

- Most miter saws are compact and portable, whereas most table saws are heavy and more stationary (but there are some more portable options). Table saws can be more expensive but there are some table saws under $1000.

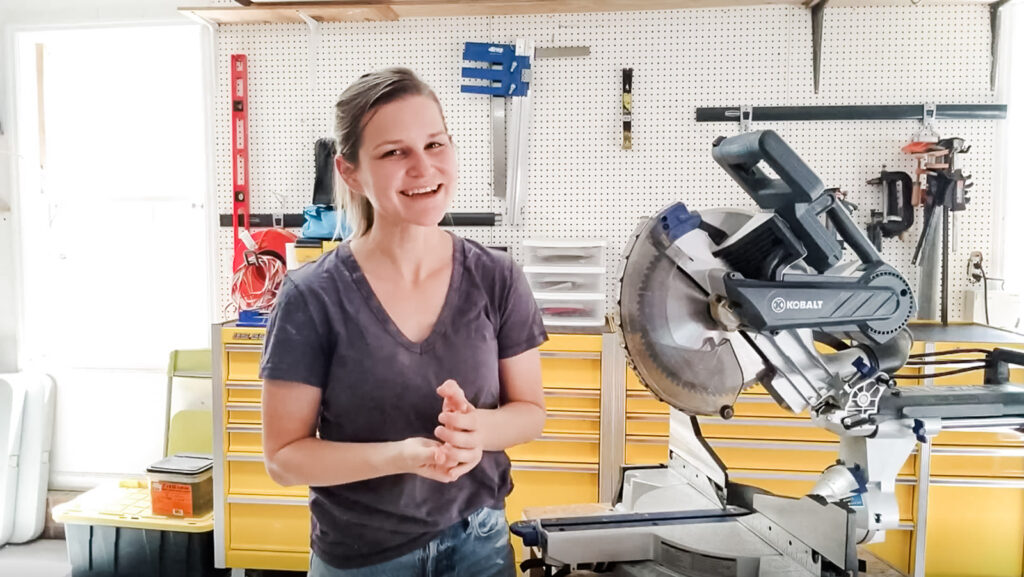

What is a Miter Saw?

Otherwise known as a chop saw—or a mitre saw in the U.K.—the miter saw is one of the first semi-stationary tools new woodworkers purchase.

With a mitre saw, you can make precise crosscuts (cuts against the grain) as well as miter cuts (angled cuts).

A miter saw can make cuts as long as its blade’s diameter, and many see this as its only shortcoming.

Check out my 10-inch vs 12-inch miter saw comparison for helping finding out which is best!

How to Use a Miter Saw

When you use a miter saw, you keep the material in a fixed position before pulling the swing arm—the part that holds the blade—down to make the cut. The blade spins downward (toward the rear of the saw).

The workpiece rests on the flat table and is pressed against the fence. The fence has a space for the blade to pass through, and the table has a slit for the same purpose.

This is unlike what you’d do to operate either a table or band saw. In those cases, the material would be pushed through while the blade spins in a fixed position.

Most miter saws are “squeeze-operated”, meaning you squeeze the handle to spin the blade. A spring keeps the saw arm and blade upright when the saw is not being used.

Most miter saws, especially newer models, come with a blade guard, and this will retract as you pull the swing arm down, revealing the blade so it’s able to cut.

Along with protecting the user, the blade guard directs sawdust to the dust shoot where it’ll be collected in a bag.

Many miter saws come with clamps, and these will keep the workpiece steady.

The miter gauge at the front is used to make miter cuts (up to 45°). Most newer saws pivot both ways, whereas older models just pivot one way (usually to the left).

A compound miter saw can tilt to make beveled cuts.

Types of Miter Saws

Compound Miter Saw: Because they can make beveled cuts, compound miter saws are often used to make crown molding and other kinds of trim. They’re also used to make picture frames and similar furnishings. Check out this miter saw vs compound miter saw comparison for more info!

Sliding Miter Saw: A sliding miter saw can make longer cuts since the blade slides on a rail. These are bigger than regular miter saws, but they’re great if you have to make deeper cuts through 1×12 or 2×12, for example.

Compound Sliding Miter Saw: This saw’s name should indicate it combines the best of what sliding and compound miter saws have to offer. You can make deeper beveled cuts, and this saw is pretty easy to handle. The sole downside is the swing arm bends in one direction only.

Dual Compound Sliding Miter Saw: Out of all these saws, the dual compound sliding saw offers the most. It slides and tilts both ways, providing superior flexibility. Making miter and beveled cuts routinely? Having this saw will save you time and help you avoid hassles.

In the market for a new miter saw? Check out these top miter saws for beginners or these great cheap miter saws!

Types of Cuts Miter Saws Can Deliver

- Crosscuts (chop cuts)

- Miter cuts (angled cuts)

- Beveled cuts

What is a Table Saw?

The table saw is hundreds of years old, and it’s stood the test of time largely because it’s an easy-to-use, versatile tool that can deliver a range of precise cuts.

Both portable and stationary table saws include the following parts:

- The Power Button: Use this to turn the saw on or off.

- The Table: This is the flat part of the saw that’s above the base.

- The Fence: This is the guide board that runs parallel to the blade.

- The Fence Dog: This is the lever that keeps the fence stationary.

- The Blade Insert: This is a thin, protective cover; it has a slit for the blade.

- The Height Adjustment Wheel: This is used to adjust the height of the blade.

- The Blade Angle Adjustment: This controls the angle of the blade.

How to Use a Table Saw

To make rip cuts, hold the wood firmly against the fence to prevent kickback.

Now turn on the saw and slowly feed the wood through it. Make sure your hand is at least six inches away from the blade as you pass the wood through.

To make crosscuts, slip the miter gauge into the designated slot. Set it at 90°.

Again, keep your fingers at least six inches away.

To make dado cuts, first put on a dado blade along with the dado insert.

Set the fence and then feed the wood into the blade to make the first dado.

Then move the fence about 1/4 inch away from the first cut before making the second pass.

Ready to purchase a table saw? Check out these top table saws for beginners!

Different Types of Table Saws

Benchtop Saw: This table saw is compact, lightweight, portable, and affordable (when compared to some of the other kinds of table saws). They’re made of lightweight materials, like aluminum and composite plastic, and they can come in handy when you’re doing small carpentry projects.

Compact Table Saws: These saws are larger than benchtop saws, but they have similar features and they’re made of the same materials. However, a compact saw can have a cast iron base, something you won’t find on any benchtop saw.

In terms of size, compact table saws are between bench top and full-size table saws; they resemble the latter more, though their rip capacity is still markedly limited.

Jobsite Saws: Otherwise known as contractor saws, these saws are more durable than benchtop and compact table saws.

They utilize belt drives along with large outboard induction motors. Their motors used to be lightweight, but as they got stronger, they got heavier. Now they weigh 200-300 pounds.

Also, these saws vibrate more than other table saws, and their duct-collection systems aren’t the best.

Cabinet Saws: The most powerful of all the table saws, cabinet saws are built to last and they can cut a range of materials. Their fences are more accurate, and they rarely require readjustment after being set.

They have powerful motors, and the blades on these saws can cut through hardwood, pressure-treated wood, plywood, pine, and sheet metals. Coming in at 500 pounds, they’re definitely sturdy, but certainly not portable.

Types of Cuts Table Saws Can Deliver

- Rip Cuts

- Crosscuts

- Bevel Cuts

- Compound Cuts

- Dado Cuts

- Rabbet Cuts

Differences Between Miter Saws and Table Saws

Miter Saw vs Table Saw: Cutting Capability and Capacity

A table saw can deliver more cuts than a miter saw, but this shouldn’t diminish the fact that a miter saw can deliver exquisite crosscuts, miter cuts, and beveled cuts. Sliding miter saws can even make rip cuts on smaller pieces.

The more basic miter saws have less cutting capacity than the more advanced ones, and the same goes for table saws.

Both saws can be used to make crosscuts, but the pull-down nature of the miter saw makes it better. It’s hard to get that kind of precision cut with a table saw, in large part because your hands are pushing it through the blade.

But when it comes to beveled cuts, rip cuts, dado cuts, and other more intricate cuts, the tables saw has the miter beat.

The quality of cuts is largely determined by the stability of the fence, the material’s grain, and the angle of the blade.

Table Saw vs Miter Saw: Size and Portability

Most table saws are bigger than most miter saws. I say most because, after all, the smallest table saws aren’t bigger than the largest miter saws.

If you have to choose one kind of saw over the other, weight should definitely be considered, especially since weight and portability go hand in hand.

Most table saws are stationary, though there are tabletop and benchtop models. Obviously, the stationary models are the heaviest and not designed for frequent transport.

Miter saws, for the most part, are tabletop saws, though there are some heavier, stationary models.

A saw’s size in part determines the woodworking projects it can be used for. For example, you shouldn’t use a miter saw to make deep rip cuts—it won’t be able to. Similarly, you can’t expect a bulky table saw to deliver precise cuts on small, thin wood.

Table Saw vs Miter Saw: Accuracy and Precision

Both saws can deliver accurate cuts, provided the material is fed properly (in the case of table saws) or fixed in place (in the case of miter saws).

Fence placement is critical as well. Both saws come with easy-to-adjust fences.

When it comes to crosscuts, the miter saw is going to deliver more precise cuts, mainly because it cuts in an up-down fashion. Also, the material being fixed in place helps a lot.

While you can get precise cuts with a table saw, these are harder to achieve because you have to feed the material through the saw. The fence is there to guide you and it’s very helpful, but if you jolt or lose control of the wood, the blade could gouge the wood and render it unusable.

That said, table saws—especially those that are stationary—provide superior stability, and this is in part why they can deliver precise cuts when fences and other stabilizing components are utilized.

When compared to handheld circular saws and similar power tools, table saws are much better at making beveled cuts. Their capacity to make bevel cuts matches that of miter saws.

Table Saw vs Miter Saw: Versatility and Flexibility

Both saws are versatile, but the miter saw offers more flexibility, in large part because it’s portable and more compact

But where a table saw lacks in flexibility, it makes up for in versatility, as it can deliver more cuts than a miter saw. Plus, it can deliver superior cuts if necessary adjustments are made and the material is fed properly.

A dual compound sliding miter saw is the most flexible miter saw because it can slide out and tilt both left and right. The most versatile table saw is the cabinet saw.

In terms of ease of use, however, the cabinet saw takes a back seat to the dual compound sliding miter saw, since it’s designed for use by professional woodworkers and craftspeople.

A dual compound sliding miter saw, on the other hand, is much easier to learn if you’re a casual DIYer.

Miter Saw vs Table Saw: Safety Features and Risks

Both miter saws and table saws come with blade guards, and both have dust disposal systems built in, making them safer than other kinds of saws.

That said, the miter saw is less dangerous, mainly because you don’t have to move the material. With a table saw, however, you have to worry about kick-back, and in the worst case scenario your guiding hand could make contact with the blade.

No matter what kind of saw you use, you should wear protective safety gear, i.e. goggles, a respirator, gloves, and clothes that cover your arms and legs, when using either saw.

Plus, the room you’re working in should be well ventilated, or you should be doing the cutting outdoors.

Overexposure to fine dust, especially the kind created by sawing engineered hardwood and sheet metal, can adversely affect your health in numerous ways.

When to Use a Miter Saw

If you need to make angled cuts or don’t have space for a table saw, this is a good opportunity to use a miter saw. They are perfect for smaller pieces of wood and making miter cuts.

Pros of Miter Saws

Compact & Portable: Miter saws are compact, lightweight, and portable, and these qualities make them attractive to DIYers and amateur woodworkers. Their size is a big part of what allows them to deliver precise cuts; there’s no material feeding, so there’s no reaching.

Great at Crosscutting: Because these saws hold the material in place, and because they cut downward toward the machine, they can deliver superior crosscuts on a range of materials. And if you use clamps, there will be even more stability, leading to even better cuts.

Great for Miter Cuts: The miter gauge is easy to use and it’s pretty reliable. If you were making miter cuts with a table saws, you’d have to feed the material at an angle, which is harder than pulling a saw arm down to make a precise, angled cut.

Bevel Cuts: Miter saws can make precise bevel cuts too. First, the miter gauge is set, and then the arm is bent to either the left or right. Because the material is fixed in place, the cut is not only clean but precise too.

Safe: The miter saw is squeeze-activated, meaning the saw blade won’t start spinning until the handle is squeezed. There’s also blade guard, and this recedes as the spinning blade is pulled down. Miter saws also come with dust-collection systems, though some are better than others.

Cons of Miter Saws

Can’t Make Rip Cuts & Other Cuts: A miter saw’s only notable downside is that it can’t make rip cuts, dado cuts, and other cuts that are frequently required. Sliding versions can make rip cuts on small boards, but even these are limited.

When to Use a Table Saw

If you need more power or a larger rip capacity, this is where a table saw comes in handy. For example, if you need to cut plywood or other larger sheets of wood, a table saw will accommodate the wood pretty easily.

Pros of Table Saws

More Cuts: A table saw can make the cuts a miter saw can make and more. They have larger rip fences, and these allow them to make deep rip cuts. Their blades are generally bigger, and they can cut wood, metal, and other materials.

Strength: Table saws utilize a circular blade just like miter saws do, but these are more powerful, in large part because machines they’re attached to are so power. Cabinet table saws, the most powerful saws on the market, have horsepower ratings from 1.75 HP to 7.5 HP.

Cons of Table Saws

Bulky: Stationary table saws may be powerful and great at providing a range of cuts, but they take up a ton of space. You can get a tabletop of benchtop version, but these won’t be able to make the sizable cuts that large stationary table saw can deliver.

Final Thoughts

In the end, table saws and miter saws are pretty similar. Both saws can deliver precise crosscuts, angle cuts, and bevel cuts, but the table saw can deliver more cuts, including rip cuts, dado cuts, and rabbet cuts.

If you can afford to have both saws, I recommend it. You’d be able to use the table saw for rip cuts and the miter saw for crosscuts, angled cuts, and beveled cuts.

The majority of woodworking tasks can be handled by both saws, and if maintained properly over the years these two power tools should last you a long time.