Spar Urethane vs Polyurethane: Which is Better? (Ultimate Guide)

Spar urethane and polyurethane are two varnishes that I use all of the time.

In many ways they’re similar, but they’re also quite different. Plus, there are many situations where one is decidedly better-suited than the other.

But which is better overall?

In this post, I’ll closely examine spar urethane vs polyurethane, which to use and when, and much more. Let’s dig in!

The biggest difference between spar urethane and polyurethane is oil content. Spar urethane is more oily than polyurethane, and therefore it’s more durable, shinier, and more resistant to a range of degrading factors. But spar urethane is also more combustible, less eco-friendly, and slower-drying because of its high oil content.

Spar Urethane vs Polyurethane

Application

Some say there’s a difference between applying spar urethane and applying poly, but I don’t think so.

I’ve brushed, rolled, and sprayed on both finishes, and neither has proven to be easier to apply.

To ensure application of either finish is easy, you need to prep your work surface properly. That is, you need to clean the surface with soap and water or mineral spirits, smooth it out with some fine-grit sandpaper, and wipe off the produced dust with a tack cloth.

In short, if you set the stage right, both spar urethane and polyurethane will perform well.

That said, you may have a tougher time with water-based spar urethanes and polys, as these tend to dry quickly. Therefore, you may run into a situation where you over-apply either finish because you can’t discern what’s been adequately coated from what’s bare.

And in the case of oil-based spar urethanes and polys, since they’re more viscous you may run into a situation where you apply too much of either finish. This makes a mess more than anything else and it can be a pain to clean up.

Here are a few tips to apply poly correctly!

Oil Content

Spar urethane is sometimes referred to as “long oil varnish”, and this is because it has a high concentration of different oils.

It is more oily than polyurethane, this is probably the most prominent difference between the two finishes.

The additional oil is what gives spar urethane its flexibility, a flexibility that allows it to withstand frequent fluctuations in both temperature and humidity.

Polyurethane, on the other hand, will crack, chip, or peel if exposed to frequent fluctuations in temperature and humidity.

High oil content is also what makes spar urethane more yellow/amber than oil-based polyurethane.

Spar urethane is used for a range of marine applications, in large part because of its high oil content. Polyurethane, while also usable, doesn’t hold up as well.

Spar urethane’s combustibility is another result of its high oil content. So before you apply this viscous finish, make sure there are no open flames around, as it doesn’t take much at all to ignite this finish.

Exterior Use

While both finishes can be used to great effect outdoors, spar urethane has a slight edge over polyurethane in this category because it’s more durable. It’s weatherproof, UV-resistant, and resistant to many other degrading elements.

Of course, polyurethane possesses many of these qualities as well, but because it doesn’t hold up well in the face of frequent temperature and humidity fluctuations, it’s more prone to getting marred outdoors.

And once a polyurethane finish has been compromised, it’s only a matter of time before the whole thing degrades and the material underneath is exposed.

Spar urethane, on the other hand, was originally designed for ship wood, which means today it’s one of the only finishes that can endure some of the most eroding elements on earth, i.e. salt water and salt air.

Spar urethane may be the better outdoor finish, but using it indoors is somewhat overkill. Polyurethane provides a tight seal, it’s waterproof, and strong overall, which means it’s perfectly suited for kitchens, bathrooms, and other rooms with many vulnerable surfaces.

Fumes

Oil-based spar urethane and oil-based polyurethane both emit fumes, and based on many years of using both I can conclude that neither one emits more fumes than the other.

Though, in theory, because it has higher oil content, spar varnish should emit more fumes.

The real difference, as far as fume emission is concerned, is between water-based and oil-based finishes.

Because of their makeup, water-based finishes don’t emit any fumes, which means they’re easier to work with, in the sense that you don’t have to be as cautious when applying these.

If you’re working with an oil-based finish, it’s important to ensure the room you’re working in—whether it be your garage, basement, or workshop—is well ventilated to prevent the fumes from overwhelming you.

Overexposure to the fumes emitted by oil-based finishes can cause dizziness, nausea, headaches, and even loss of consciousness.

Overwhelming fumes should also be a sign of how flammable these finishes are in viscous form.

To ensure you’re as safe as can be when applying oil-based finishes, wear glasses, a respirator, and gloves.

Wondering how shellac stacks up? Check out this shellac vs polyurethane comparison for more info!

Drying Time

I’ve read that spar urethane dries quicker than oil-based polyurethane, but I have yet to experience this for myself. And on a logical level, it doesn’t make sense that something with more oil would dry quicker.

In my experience, both finishes take about the same time to dry, whether we’re talking about oil-based or water-based versions. That is, oil-based spar urethanes and polyurethanes take five to seven hours to dry, whereas water-based spar urethanes and polyurethanes take one or two hours to dry.

Regardless of what a manufacturer recommends, I always let a finish dry for longer. This way there’s less risk of me sanding too early, messing up my sandpaper, making a mess, and essentially having to do all the work I did hours ago—again.

Price

As far as price is concerned, there’s not much difference between spar urethane and polyurethane. Of course, with either finish you’re going to pay more for enhancements, like faster drying or more flexibility, but the basic versions are comparable in price.

I’ve found that spray finishes are generally more expensive than liquids, and I believe this is mainly because of the convenience; other woodworkers I’ve talked to, online and in person, agree.

When considering price, it’s important to consider durability and lifespan too. After all, the product that can last longer and hold up well all the while will get you the best bang for your buck.

So with durability and lifespan taken into account, one can argue that spar urethane is generally more cost-effective than polyurethane.

When to Use Spar Urethane

While it’s true that spar urethane can be used to coat cabinets, vanities, and a range of other indoor furniture and furnishings, it’s truly unnecessary to use such a strong finish when polyurethane is suitable.

It’s best to use spar urethane on outdoor wood projects, outdoor furniture, etc., as this way you can take advantage of it being weatherproof. And since it resists UV rays well, you won’t have to worry about the sun damaging or discoloring it.

Spar urethane is also ideal for marine applications, like offshore structures, boats, and docks.

Additionally, spar urethane is ideal for surfaces that won’t be discolored by its oily nature but can benefit from its durability.

Most woodworkers avoid using spar urethane on softwood, for example, because of its discoloring impact.

When to Use Polyurethane

Polyurethane is better suited for indoor applications, as these don’t require strength and protection as much as they require visual appeal.

Plus, polyurethane is an effective sealer, which means if you apply it to cabinets, drawers, vanities, desks, shelves, etc., you don’t have to worry about these furnishings being damaged by water.

In short, it’s wise to apply this finish to any indoor wooden surface that’s especially at risk of being dinged, scratched, etc.

While exterior polyurethane can be used outside to great effect, if you’re in an area where the temperature and humidity fluctuate often, even this polyurethane won’t hold up well for long.

What is Spar Urethane?

Spar urethane is a self-leveling, oily, durable sealer, one that can protect a range of hardwoods, softwoods, and wood-based materials, including medium-density fiberboard (MDF), oriental strand board (OSB), and plywood.

The spar urethanes most woodworkers use are oil-based, though there are water-based spar urethane versions as well.

It’s a mostly clear finish, but due to the high concentration of particular resins, it can display a yellowish tint once cured.

Originally designed for ship spars—hence the name—this finish is weatherproof, meaning it holds up well in the face of high winds, non-stop rain, sudden and wide temperature fluctuations, and direct sunlight.

Spar urethane is also flexible, which means in especially humid climates—where wood is more prone to expanding and contracting because of the fluctuations in humidity—it is able to expand and contract with the wood, ensuring a tight seal and protection all the while.

What Does Spar Urethane Look Like?

Spar urethane comes in several sheens, including glossy, semi-gloss, and satin. Glossy spar urethanes are particularly shiny, while satin versions have some shine but are muted for the most part.

Pros of Spar Urethane

- Versatile: Spar urethane can be used for both indoor and outdoor applications, but it’s mainly used outdoors. It can be applied to a range of woods and wood-based materials, and the more porous a surface is, the easier it’ll be for the spar urethane to take hold, cure, and look great.

- Durable: In addition to being weatherproof and UV-resistant, spar urethane is generally durable, meaning it doesn’t dent, scratch, or gouge easily. Its durability is a main reason why its applied to surfaces that are at a higher risk of getting damaged.

- Easy to Apply: Spar urethane can be brushed, rolled, or sprayed on, though the project will largely dictate which method of application is best. But applying spar urethane is far from difficult; the most challenging thing is being patient enough to let it cure completely.

Cons of Spar Urethane

- Long Curing Time: It takes spar urethane five to seven hours to become mostly dry, but it may be 30 days before it’s completely cured. However, if you choose a water-based spar urethane over an oil-based version, you’ll spend less time waiting, as water-based spar urethanes take a week or two to fully cure.

- Rich in VOC: Volatile organic compounds (VOC) are harmful to humans, and spar urethane contains a lot of them. Therefore, you should take precautions before working with this finish. Sustained exposure to VOC can lead to adverse health effects, including irritation of the eyes, nose, and throat, headaches, nausea, kidney failure, and liver damage.

- Emits Strong Fumes: Oil-based spar urethanes emit strong fumes, which means you should only apply this finish in a space with good ventilation. Overexposure to the fumes can cause headaches, nausea, and loss of consciousness.

Oil-Based Spar Urethane vs Water-Based

In many ways these spar urethanes are similar, but their differences are what prompt woodworkers to choose one finish over the other.

Oil-based spar urethane is more viscous, combustible, less eco-friendly, slow-drying, and more harmful (due to its high concentration of VOC).

Water-based spar urethane, on the other hand, is thin, not combustible, more eco-friendly, quick-drying, and less harmful.

In short, there are times when an oil-based spar urethane is ideal, like when you need a strong finish for an outdoor wooden structure. And there are other times, like when you need to finish custom-made kitchen cabinets, when a water-based version is best.

What is Polyurethane?

Just like spar urethane, polyurethane is a durable sealer that’s applied to a range of materials, and there are both oil-based and water-based polyurethane options.

Polyurethane is often applied to flooring, furniture, stairs, door and window frames, molding, and other wood or wood-based surfaces.

In addition to being a durable finish, polyurethane is moisture-resistant, meaning it’s fungus- and mildew-resistant too.

A heat- and corrosion-resistant finish, it’s used often in kitchens, bathrooms, and other interior spaces that can get quite hot.

While its durability for the most part matches that of spar urethane, the latter finish is more flexible. In other words, polyurethane doesn’t hold up well against sudden fluctuations in humidity.

What Does Polyurethane Look Like?

Polyurethane comes in different sheens, specifically glossy, semi-gloss, and satin. You can tell an oil-based acrylic polyurethane has been applied to a wooden surface if it has a yellowish tint. Water-based polys, on the other hand, dry clear. The shiniest polys are the oil-based ones, while water-based polys have a more muted sheen.

Note: It’s true that most polyurethane finishes look a little cloudy, but if you apply a polyurethane finish and it looks exceptionally cloudy once cured—that is you can barely make out the details of the wood surface underneath—it’s likely you applied the polyurethane clear coat all wrong.

Need more help choosing the right finish? Check out my lacquer vs polyurethane comparison for more help!

Pros of Polyurethane Wood Finish

- Durable: Polyurethane’s durability is the main reason why it’s applied to a range of wooden surfaces. It resists dents, scratches, and gouges well, and its durability also ensures it’s long-lasting no matter what it’s forced to endure.

- Resistant: Both oil- and water-based polys are resistant to a range of degrading elements, like water, heat, chemicals, fungi, and solvents. In addition to being weatherproof, polyurethane is also UV-resistant, so it can be used outdoors to great effect.

- Tight Seal: When you want to prevent water from seeping through wood joints, applying polyurethane is a smart move. This is a terrific sealer, as it fills gaps and cracks well and holds up once fully cured.

- Easy Application: You can apply polyurethane with a roller, foam brush, or even by spraying. And all you need to apply this finish is some sandpaper, one of the applicators above, one or two clean cloths, patience, and time. By applying polyurethane correctly, you can avoid brush strokes, air bubbles, and other poly mistakes that can ruin your project.

- Cost-Effective: Polyurethane is a cost-effective finish, mainly because of its durability and lifespan. Think about the bang for your buck you’re getting when you apply $20-$30 worth of polyurethane to protect a very expensive piece of furniture—that kind of value is unmistakable.

Cons of Polyurethane Wood Finish

- High VOC Concentration: Oil-based polyurethanes in particular have a lot of VOC. So if you coat a piece of frequently used furniture in this, there’s a greater likelihood that you’ll be exposed to these VOCs (in vapor form) over the long term. Again, overexposure to VOC can lead to a range of health problems so be sure to use the proper safety gear when applying polyurethane.

- Fumes: Polyurethane, especially oil-based products, usually emit strong fumes. Therefore, when you apply this the room you’re in should be adequately ventilated so you don’t breathe in a high amount of fumes and suffer the consequences.

- Discoloration: Oil-based polyurethane can discolor wood and wood-based materials, especially softwoods. Since more viscous polyurethanes, i.e. the ones with high oil content, turn yellowish or amber once fully cured, they can discolor the painted or stained material they’re applied to.

- Long Curing Time: Like with spar urethane, you’ll need to wait five to seven hours for this to be 70-80% dry. To be fully cured, however, polyurethane will need a few weeks to reach this state.

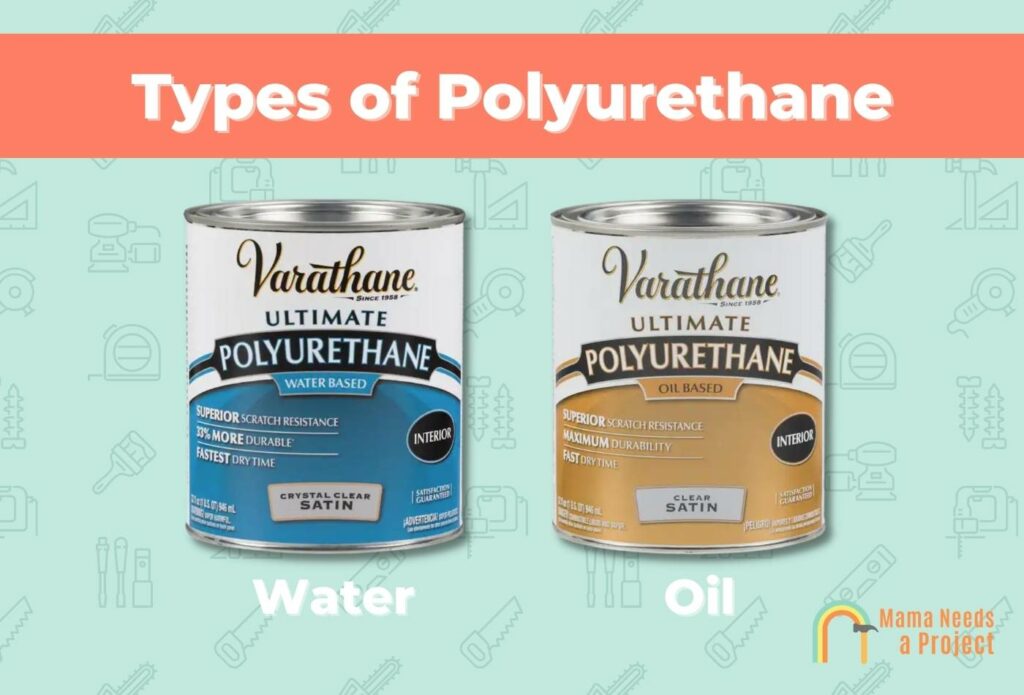

Oil-Based Polyurethane vs Water-Based Polyurethane

The two main kinds of polyurethane are water-based and oil-based.

Water-based is thinner, quick-drying, contains very little VOC, is not combustible, emits less fumes, and is more eco-friendly overall than oil-based poly.

Despite being weaker than oil-based poly, it dries clear, which means it’s great for applications that require visual appeal more than durability.

Oil-based poly, on the other hand, is combustible, rich in VOC, more viscous, slow-drying, and less environmentally friendly overall.

It’s mainly used outside rather than inside, for if you coat an outdoor structure with this it’ll be weatherproof, UV-resistant, rot-resistant, etc.

Spar Urethane vs Polyurethane for Floors

Since floors are always bearing the brunt of foot traffic, it makes sense that they’re only coated with the strongest finishes. In this case, it’s spar urethane.

Applying spar urethane to wood surfaces, whether it be a floor or tabletop, ensures a smooth finish. And despite being oily, you won’t have to worry about the floor being slippery once the spar urethane has had time to cure completely.

FAQs

Can I use spar urethane instead of polyurethane?

Yes, there are numerous instances where it’s better to use spar urethane over polyurethane. For one, spar urethane holds up better in harsh environments. Also, the durability spar urethane possesses is unmatched by polyurethane.

Which is more durable urethane or polyurethane?

Of these two varnishes, spar urethane is more durable, and for this reason (among others) it’s often applied to exterior surfaces.

And whereas spar urethane can be used as a marine varnish, polyurethane can’t.

Multiple polyurethane coatings can collectively be more durable than one layer of spar urethane, but overall spar urethane is tougher and therefore longer lasting.

What is spar urethane used for?

Spar urethane was created to protect spars and other wood surfaces on ships, and these days it’s used to coat everything from outdoor furniture to floors and stairs. If there’s a chance that wood is going to expand, usually spar urethane is applied to it, as this is flexible enough to expand and contract with the wood.

Final Thoughts on Spar Urethane vs Polyurethane

In the end, both finishes can be used on a range of applications, but when weatherproofing, strength, and general toughness are important, opting for spar urethane over polyurethane is a wise move.

But just know that spar urethane’s extra durability comes at a cost. Specifically, it’s slow-drying, combustible, less eco-friendly, high in VOC, and often discoloring.

So which is the winner in the contest of spar urethane vs polyurethane? Well, it’s more or less a tie, with a slight edge going to spar urethane.