What Is Manufactured Wood (Pros & Cons, Best Types, and More!)

Manufactured wood has become more and more popular over recent years and it’s for good reason. This type of wood boasts many advantages over natural wood, which is why it’s often used for a variety of projects.

Here’s exactly what manufactured wood is and when you should use it!

Manufactured wood is made of wood fibers and resin that is mixed together and pressed into boards. It’s commonly used for flooring, decking, furniture making, and a variety of other projects. In most cases, it’s cheaper than natural wood.

What is Manufactured Wood?

Manufactured wood was invented to resemble natural wood at a cheaper price point while maintaining the strength and durability of natural wood.

Rather than coming directly from a tree, manufactured wood is made by gluing together several components. Most forms of manufactured wood are created from a combination of wood chips and resin.

Although relatively new, manufactured wood is becoming more and more popular on the market.

As with any wood, there are multiple varieties of manufactured wood with some being higher quality than others. As manufactured wood is still relatively new, there are still improvements made to the manufactured product.

Pros of Manufactured Wood

- Smooth and flat surface: Manufactured wood is created with a smooth and flat surface. You don’t get the flaws of traditional wood on the market like knots, cracks, and additional lines.

- Cheaper: Some forms of manufactured wood are significantly cheaper than their natural counterparts. You can save a decent amount of money with manufactured wood.

- Versatile: Manufactured wood is much more versatile than natural wood, making it ideal for many projects and simple to cut.

- Durability: Manufactured wood created under the right circumstances is sturdy and will last a long time.

- Flexibility: The unique makeup of manufactured wood allows it to be more flexible than natural wood.

- Environmentally friendly: Manufactured wood doesn’t come from cutting down a tree. It’s made from scraps, making it more environmentally friendly than natural wood options.

Cons of Manufactured Wood

- Minimal resistance to moisture and humidity: Manufactured wood isn’t made to be resistant to moisture and humidity. There is a high risk of the material soaking up water.

- Heavy and sturdy: Manufactured wood can be heavy and sturdy. While that’s not a bad thing, it makes it tricky to handle if you are just one person completing a project.

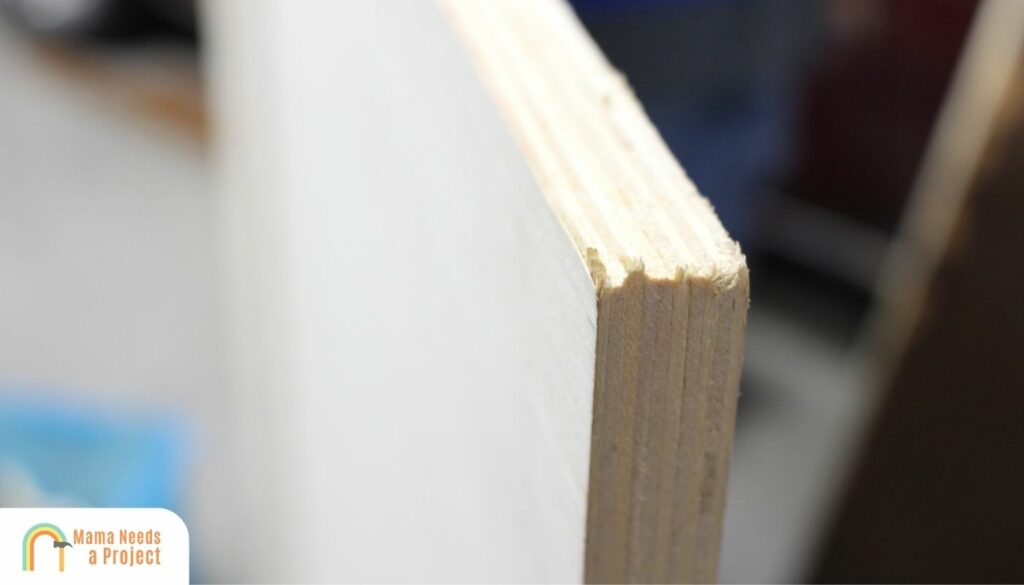

- Veneers showing at the edges: The construction of manufactured wood may leave rough edges. These require more work to remove than natural wood.

- Formaldehyde: Manufactured wood is often made with formaldehyde. When cut, the dust from manufactured wood can release carcinogens into the air. It can harm the user if proper precautions are not taken in the cutting process.

Is Manufactured Wood Durable?

Manufactured wood can be just as durable as natural wood in some cases. However, it depends on the manufacturing process and the materials used.

For example, low end furniture made of particle board is not nearly as durable as solid wood furniture.

However, using manufactured deck flooring can actually be much more durable than solid wood.

Ultimately, it depends on the type and quality of the manufactured wood you choose.

Types of Manufactured Wood

Manufactured wood is a variety of wood rather than a specific material.

There are several types of manufactured wood and all of them have something different to offer. Below are some of the most common.

Medium-Density Fiberboard

Medium-density fiberboard is the type of manufactured wood most people think of when it comes to engineered wood.

It’s a thick product that shows a powerful yet flexible surface to cut through. Woodworkers enjoy MDF for the flawless surface it offers and the unique strength it possesses.

This product begins as a pile of sawdust and shavings. From there, it is dehydrated and then added into resin and wax, where it’s mixed until combined. The mixture is then exposed to heat and pressure until it becomes a complete medium-density fiberboard.

MDF is relatively strong considering it’s a man made wood, but it’s not quite as strong as real wood.

Despite its similarity to natural wood, MDF tends to be more affordable than its counterpart.

Although MDF contains potential toxins, many enjoy the affordability and ease of use. Some projects work well with MDF.

Plywood

Plywood is the next manufactured wood that you’ve probably heard of.

I think many have heard the word so many times they assume plywood is a plank of natural wood, but it’s not. This product is one of the most widely known pieces of engineered woods. You can find it at just about any hardware or lumber store in the United States.

Plywood is made by taking multiple layers of plys or softwood veneer and gluing them together. They are glued perpendicular to the layer before, allowing for a crossing system that adds to the strength and durability of the wood. The layers are solidified with formaldehyde and then pressed with high pressure and heat.

Plywood comes in handy for uses that are both structural and non-structural. It works as floor sheathing, sub-flooring, roof sheathing, and more. It’s both practical and affordable making it a great option for many projects.

While plywood is a great manufactured wood, it does have some cons. One con is that it’s not as strong as MDF. It’s also not as resistant to water and humidity, so you’ll need to waterproof your plywood if you’re using it for projects that will be exposed to moisture.

Veneer Wood

A veneer is a thin wood material that goes on the surface of a project, acting as a cover for whatever is underneath.

There are plenty of natural wood veneers available. In recent years, engineered wood veneers became a popular choice for homes that wanted affordability and durability.

Veneer wood comes from trees, so it’s different from the other manufactured wood varieties. Rather than going through natural processes, the manufactured veneer wood is placed in templates and dye molds that give it the desired shape.

The result is a wood veneer that’s free of the knots and cracks that accompany traditional wood while still holding to the natural look of the wood grain.

This type of wood is often used in cabinetry, flooring, and other areas where a natural wood look is desired. It’s also more affordable than using real wood, making it a popular choice for budget-conscious homeowners.

Fiberboard

Fiberboard is a manufactured wood product that works well for many projects. It’s a low-density, flat wood that’s a competitor with particleboard.

Fiberboard is created by taking leftover pieces from wood projects and bringing them together with a resin or similar glue. It is very similar to particleboard – with one critical difference. Fiberboard is stronger than particleboard and made with much smaller pieces of wood.

The product has a smooth surface and is simple to paint and cut, although it has trouble holding a stain.

Particleboard

Another type of manufactured wood that is extremely common is particleboard.

It’s a low-density, flat board, also known as chipboard. It is one of the easiest types of manufactured wood to create and a very affordable option for a variety of projects.

Particleboard is made by taking wood chips and mixing them with resin or another form of glue bond. Compared to fiberboard, particleboard is made with larger pieces of wood.

Many individuals use particle board as a substitute for plywood in furniture creation, floor decking, underlayment, countertop substrate, and more. You can paint particle board, giving you whatever appearance you desire.

Of course, it’s critical to remember that particleboard is made using formaldehyde. If cut incorrectly, it can release dangerous chemicals that can harm if inhaled.

Uses for Manufactured Wood

Flooring

One of the most prominent locations you will see manufactured wood is flooring.

This can be anything from hardwood floors to laminate. With engineered hardwood, a plywood or fiberboard core is topped with a veneer of the hardwood species of your choice.

There are several benefits of choosing manufactured wood flooring including:

- It’s more affordable than natural wood flooring

- It’s easier to install

- It’s less likely to warp or cup

- There’s a wider variety of colors and styles to choose from

Subflooring is another common use for manufactured wood. Plywood and fiberboard work as subflooring options, providing a layer between the top wood and everything underneath.

Engineered wood has a look that you either love or hate. However there are some other advantages you’ll want to consider before making your final decision.

Decking

Decking is another extremely common place where manufactured wood can be beneficial.

In recent years, there has been a massive shift from the use of real wood to manufactured wood, and for good reason.

Because of the construction of manufactured wood, it can last much longer than regular wood. It’s also easier to install and can be found in a wide range of colors and styles.

Of course, not every type of engineered wood works well for decking so it’s important to do your research to find one that works for your needs.

It’s also worth noting that many manufactured woods that are designed for decking are more expensive than real wood.

But because of how long they can last, it’s often worth the money. After all, who wants to spend the time and money to replace a deck every few years?

Cabinetry

Cabinetry is one of the most popular places to use engineered wood products.

This is because it’s extremely strong and can be found in a wide range of colors and styles which are perfect for cabinets.

Furniture Making

The final place manufactured wood often appears is in furniture.

It serves as an easier and cheaper way to cut out shapes and create a solid structure that can then be draped with fabrics and upholstery.

One of the most popular types of manufactured wood for furniture is MDF.

It’s critical to note that furniture made with manufactured wood won’t last as long as furniture created with actual wood.

If you want to save money on furniture, go with manufactured wood for your next project. If you want to extend the time you spend as an owner, I recommend sticking with natural wood, if you can afford it.

Manufactured Wood vs Solid Wood

Manufactured wood and solid wood are the two options when you’re looking for wood to use in a project

But what are the key differences between the two?

The advantages of manufactured wood include:

- Affordability: Many varieties of manufactured wood are cheaper than their natural counterparts.

- Strength: Well-made manufactured wood is incredibly strong and durable.

- Smooth surface: Manufactured wood has a smooth, perfect surface.

- Fire resistant: Some manufactured wood types are fire resistant.

When it comes to solid woods, here are a few advantages:

- Beauty: There is a natural beauty that comes with solid wood.

- Lack of toxins: There are no toxins in natural wood.

- Readily processed: Natural wood is readily processed and prepared for you to use.

- Strong: There is a unique strength in solid wood that is extremely difficult to replicate.

- Recyclable: you can easily recycle solid wood

There are pros and cons to each type of wood. It’s up to you to examine your project and personal preferences to determine which product is ideal.

Are there Toxins in Manufactured Wood?

Although most types of manufactured wood won’t release toxins, they are made with toxic materials.

These can prove dangerous in certain instances, such as cutting wood in a confined area.

Chemically engineered wood is formed with formaldehyde. This chemical shouldn’t leech from the product but can be released when cut or used.

Is Manufactured Wood Safe?

Manufactured wood has been around for quite some time. It was first introduced in the 1930s as a way to create strong, durable products without having to use as much natural resources.

Over the years, it’s become an extremely popular product for a wide range of applications but some have risen concerns over the materials used inside of it, namely formaldehyde.

While there are some dangers associated with manufactured wood, it is still considered a safe product.

As long as you aren’t cutting it in a small, confined area, you should be safe.

Final Thoughts

Manufactured wood is an engineered material that’s constructed to resemble, act, and feel just like solid wood.

It’s made from wood fibers, particles, and veneers that are bonded together with adhesives and pressed into sheets or boards resulting in an end-product similar to wood.

It’s often used in construction, decking, furniture-making, flooring, and many other applications.