Table Saw vs Circular Saw: When to Use Each! (Ultimate Guide)

Table saws and circular saws are two of the most commonly used saws, so it should come as no surprise that these saws are often compared.

Both saws have attractive qualities, and these make them great for a range of cutting tasks. But which is better overall between a table saw and circular saw?

In this post, I’ll compare a table saw vs circular saw, which is better for your projects, and much more. Let’s dig in!

- Table saws are powerful stationary saws that can deliver a wide range of cuts. They aren’t the most affordable saws, but they’re accurate, durable, and easy to use.

- Handheld circular saws can provide most of the cuts that table saws can, but they’re not as accurate nor as powerful. They are, however, compact, lightweight, and more affordable.

What is a Table Saw?

Table saws are large, versatile saws that have been around for hundreds of years, and they can deliver a range of cuts, including: rip cuts, crosscuts, miter cuts (angled cuts), rabbet cuts, bevel cuts, groove cuts, and dado cuts.

Table saws utilize blades of all sizes, but the 10” saw blade is the most common.

Table Saw Components

All table saws include the following components. Advanced models have more, but these are the essential components that distinguish table saws from other saws:

- The Power Button: This turns the system on and off.

- The Tabletop: This is the flat, uppermost section of the saw; it’s above the throat plate.

- The Throat Plate: This is the slitted section through which the blade cuts.

- The Blade Insert: This is a thin, protective cover; it has a slit for the blade.

- The Rip Fence: This is the guide board that runs parallel to the blade.

- The Fence Locking Handle: This is the lever that keeps the fence stationary.

- The Height Adjustment Wheel: This is used to adjust the height of the blade.

- The Miter Gauge: This allows you to make angled cuts.

- Tilt Hand Wheel: This allows you to tilt the blade so it can make beveled cuts.

Check out some of the best table saws for beginners looking to start woodworking!

Types of Table Saws

Benchtop Saws

Compact, lightweight, and portable, benchtop table saws are the smallest kind of table saw, and they’re also the most affordable.

They’re made of lightweight materials like aluminum and composite plastic, and they can weigh anywhere from 45 to 100 pounds.

Since they’re lightweight and portable, you won’t have any problem bringing them to and from job sites.

They can deliver the same cuts as larger models, but they are restricted by their small size.

In short, they’re ideal for woodworking hobbyists because they’re compact and easy to use, and those who need a portable table saw can also utilize them to great effect.

Job Site Saws

Job site saws, or contractor saws as they’re commonly known, are more durable than benchtop saws, so they can make precise cuts in heavy-duty materials.

Unlike benchtop saws, job site saws have belt drives and outboard induction motors.

Today, they weigh 200-300 pounds, but they used to be lighter; they got heavier when their motors got more powerful.

These saws vibrate a lot, but this doesn’t prevent them from making clean cuts. Also, they lack an efficient dust-collection system.

Most job site saws have wheels; those that don’t usually just have a four-legged stand.

Cabinet Saws

Cabinet table saws are by far the most heavy-duty of all the table saws. When equipped with the right blade, a cabinet saw can cut through virtually all materials.

Their fences are more accurate, meaning after you set the fence you won’t need to adjust it again. They’re safer too.

But they can weigh more than 500 pounds, so they’re definitely not the most portable table saws. The main reasons why they’re so heavy are:

- They have high-powered motors

- They’re made of durable materials

But their power, precision, and versatility come at a cost, as these are the most expensive table saws.

Types of Cuts Table Saws Can Perform

- Rip cuts

- Crosscuts

- Bevel cuts

- Dado cuts

- Rabbet cuts

- Groove cuts

How to Use a Table Saw

Rip Cuts

To make a rip cut, first set the rip fence. The cutting line should be aligned with the blade when the workpiece is pressed against the rip fence.

Now get the table saw blade spinning before slowly feeding the piece through. Always keep your hands at least six inches away from the blade as you feed the wood.

Crosscuts

To make crosscuts with a table saw, set the miter gauge to 90°. Then set the rip fence. When you’re ready, feed the workpiece through the table saw blade.

Bevel Cuts

You’ll need to tilt the table saw blade to make a bevel cut; this can be done with the tilting mechanism that’s under the table.

Once the blade is at the desired tilt, set the rip fence and miter gauge.

When making bevel cuts, it’s nice to have the space that a large, stationary table provides.

Dado, Groove & Rabbet Cuts

These cuts are mainly for joinery.

To make them, you’ll need a dado blade and the corresponding insert. This blade is much blunter than your average circular saw blade.

Making these cuts is pretty much like making cuts with a regular blade. That is, you set the fence, the miter gauge (if you need it), turn the blade on, and start feeding.

If you need more help using a table saw, check out the video below!

What Materials Can Table Saws Cut?

These saws are mainly used to make precise cuts in hardwoods and softwoods, but they can cut other materials as well.

For example, table saws can also cut plexiglass, plastics like polycarbonate and acrylic, but they tend to damage these materials because they’re so powerful.

They can cut soft metals like brass and aluminum too, provided the right blade is attached.

You shouldn’t cut medium-density fiberboard (MDF) on a table saw, as too much dust will be created, and overexposure to this dust can adversely affect your health in numerous ways.

Stone is another material that shouldn’t be anywhere near a table saw. These saws may be able to deliver perfectly straight cuts in woods and other materials, but they tear up stone, tile, etc. because they’re so powerful.

What is a Circular Saw?

Circular saws are compact, versatile handheld saws that, when equipped with the right circular blade, can cut through a range of materials, including wood, stone, sheet metal, plastic, and ceramic.

There are cordless and corded circular saws, but cordless circular saws are the ones most people own.

Check out some of the best circle saws for beginners if you’re in the market for a new saw!

Circular Saw Components

Circular saws contain the following components:

- The handle

- The trigger switch

- The blade

- The blade guard

- The shoe/baseplate

- The height adjustor

- The bevel adjustor

Note: If you have a newer model or one that’s meant for commercial use, it probably has more components. These, however, are the main ones.

Types of Circular Saws

Worm-Drive Circular Saws

A worm-drive circular saw is a powerful handheld saw that can cut thick materials like hardwoods. These are direct-drive saws, meaning their motors are attached directly to the blades.

These are heavier and more expensive because of their many appealing qualities and capabilities.

Sidewinder Circular Saws

Sidewinder saws don’t have as much torque as their worm-drive counterparts, but they’re lighter, more compact, and more affordable.

On a sidewinder circular saw, the motor is attached to a gear that’s attached to the blade; this arrangement is a main reason why it’s less powerful.

These saws do, however, spin faster, which is important if you’re making precise cuts.

If you want a strong sidewinder circular saw, but you don’t want extra weight, get a sidewinder circular saw that has helical gearing, as these provide more torque.

Circle saws are also pretty similar to track saws. You can read my circle saw vs track saw comparison for more info.

Types of Cuts Circular Saws Can Perform

TextA circular saw can make rip cuts and crosscuts. It can make miter cuts too, provided a speed square is used. Bevel cuts will require a speed square as well.

How to Use a Circular Saw

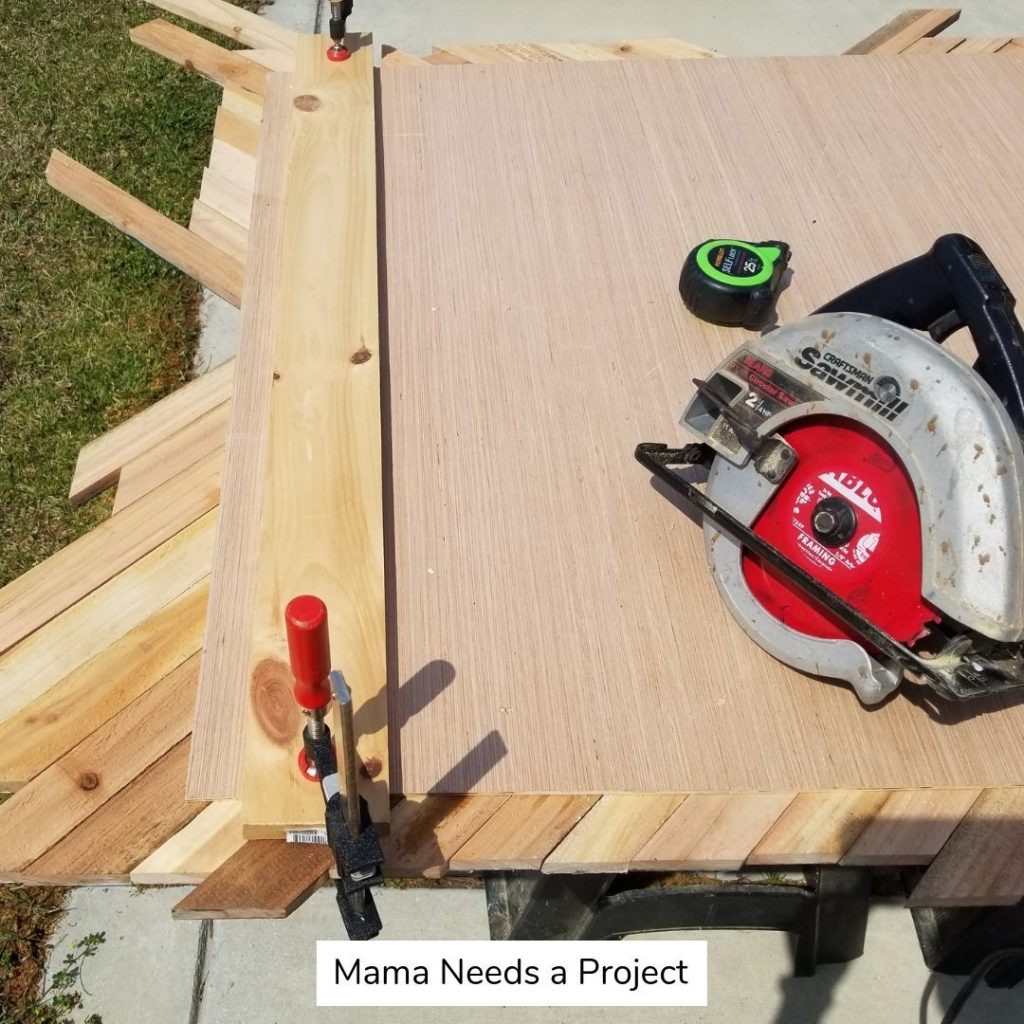

A circular saw can make a variety of cuts, but in order to make precise cuts you need to be familiar with it, as there’s no fence.

However, you can use a speed square to ensure precise, straight cuts.

To make a rip cut, first draw the cutting line on the workpiece. Once you have a visible line, and the workpiece is ready to be cut, rest the front of the shoe on the workpiece. Now squeeze the handle to spin the blade. Carefully move the saw forward to make the cut.

You’d essentially do the same thing to make a crosscut; the only difference is you’ll be cutting against the grain (as opposed to with it).

To make miter and bevel cuts, it’s best to use a speed square. Make no mistake you’ll need a bit of finesse to make these kinds of cuts with a circular saw.

So if you’re not a master with this handheld power tool, it’s best to leave the more intricate cuts to the table saw; even a compact benchtop saw will do.

Check out the video below to learn how to use a circular saw!

Differences Between Table Saws and Circular Saws

Size & Portability

Handheld circular saws are much smaller than table saws, and they weigh less too (obviously).

In fact, when you think about it, a circular saw is pretty much a handheld version of the table saw; they use the same blades and they make the same cuts.

Circular saw blades are usually 4.5-7 inches, whereas table saws utilize 10-inch blades.

Because they’re compact, circular saws are a lot more portable than table saws. However, a benchtop table saw is pretty portable.

The difference in size also in part explains why circular saws are cheaper than table saws.

Cutting Capacity & Versatility

Both saws can make perfectly straight cuts, but it’s easier to get these with a table saw, since these have rip fences and wide, smooth surfaces.

That said, a good circular saw can deliver most of the precision cuts a table saw can deliver.

Where the table saw has the circular saw beat, however, is its ability to make dado, grooved, and rabbet cuts for joinery.

Most table saws are more powerful than most circular saws, but this shouldn’t diminish the fact that circular saws are great for cutting wood and other materials.

Plus, someone who knows their way around one of these power tools can deliver accurate cuts faster than a table saw.

Accuracy & Precision

If accuracy and precision are what you’re looking for, it’s best to use a table saw. These can make clean, straight-line rip cuts, and they can also make miter and crosscuts.

In fact, a table saw can make miter cuts just as well as a miter saw, provided the miter gauge and fence are used properly.

And because you can easily adjust the cutting depth on a table saw, you can cut wood and many other materials, whether they’re thin or thick.

Table saw blades tend to be more powerful too, and this can help with achieving precision cuts, provided the material you’re cutting isn’t negatively affected by too much power—like certain plastics, for example.

Safety Features

Generally speaking, table saws are safer than circular saws.

Both saws have safety features, of course, but a handheld circular saw is operated closer to the body, and this alone makes it more dangerous.

Plus, most circular saws don’t have sawdust collection systems like table saws. That said, a lot of table saw dust-collection systems are nothing to write home about.

No matter what kind of saw you’re using, you should always have on a respirator, goggles, gloves, and all your skin should be covered.

Also, you should be sawing in a well-ventilated area; there should be at least two windows open and the fan or two running.

Price

Circular saws are cheaper than table saws, mainly because they’re smaller and therefore don’t have as many components.

Also, circular saws aren’t as durable as table saws, and this too is a reason for the discrepancy in price.

The average table saw is $200-$500, whereas the average circular saw is $60-$120.

Even the smallest, most basic versions of the table saw are more expensive than the majority of top-tier circular saws.

When to Use a Table Saw

If you’re working on a larger project with larger sheets of wood (think plywood) and you require a clean cut – using a table saw is the way to go.

Pros of Table Saws

Versatile

A table saw can make more cuts than other saws, and its versatility is a main reason why it’s been a sought-after saw for so long. And unlike other saws, a table saw can cut numerous materials, even those that are hard and dense.

Powerful

Table saws are powerful saws, and its their power which allows them to make precise cuts through a range of materials. These are corded saws for the most part, but the smaller, more portable table saws are cordless.

A table saw’s power can be a downside, however, because it prevents the saw from making clean cuts in stone, ceramic, and similar materials.

Accurate

For the most part, table saws get their accuracy from their rip fences, miter gauges, etc. In other words, if they didn’t have these components, making accurate, straight cuts would be harder.

Safe

These saws are safer, since they have blade guards and other safety features. Also, since the blade operates a considerable distance from the user’s hands, arms, and body, an accident is much less likely.

Cons of Table Saws

Bulky

A table saw will take up a lot of space, and this is one reason why woodworking hobbyists tend to use the smaller table saws; they’re compact, portable, and easy to store.

Complicated

It’ll take some time to get used to a table saw. But once you get the hang of things, you can use this saw to make intricate cuts that other saws have a hard time achieving.

When to Use a Circular Saw

If you’re working on a smaller project and need more portability, using a circular saw makes sense.

Pros of Circular Saws

Compact

Because they’re compact, handheld circular saws are easy to store. Plus, you can take them to a job site, as they’re portable and lightweight.

Versatile

These saws are pretty versatile, as they can deliver most of the cuts a table saw can deliver. Also, because they’re small and lightweight, they can cut through structures, provided the material allows for this.

Affordable

Handheld circular saws are a lot cheaper than table saws. Even the advanced models are cheaper than budget-friendly benchtop saws.

Cons of Circular Saws

Less Powerful

Corded and cordless circular saws aren’t as powerful as table saws, so it’s harder for them to make clean cuts through dense material.

That said, the reduced power is somewhat beneficial, since these saws can cut through stone, ceramic, etc.

Final Thoughts

In the end, table saws and circular saws both have qualities and capabilities that make them great for a range of cutting tasks, but the table saw is more powerful, more durable, and more precise than the handheld circular saw.

But the circular saw is compact and portable, and it’s also cheaper.

You can’t go wrong with either saw, but if you need to cut perfectly straight lines day in and day out, it’s smart to invest in a fully equipped table saw.

If you’re only going to be doing small woodworking tasks, there’s no need to get a bulky, expensive table saw; a well-built circular saw will do just fine!