How to Harden Wood (EASY Methods!)

Wondering how to harden wood?

If you’re using a soft wood on your project – there’s a good chance you’ll want to give it some extra strength and durability. And it’s easier than you think!

In this guide, I’ll show you exactly how to harden wood so you can improve the strength and durability of any wood surface. Let’s dig in!

- Different types of wood have varying degrees of hardness, but you can make any type of wood harder by using a wood hardener, applying epoxy or polyurethane, or using heat.

- Hardening wood brings out its natural beauty and increases the structural integrity of the wood – which can be essential for some projects.

How To Harden Wood

Method 1: Fire

The fire hardening method is the oldest in the book. It’s hard to say when people started using fire to harden wood, but there’s a strong chance it occurred shortly after the discovery of fire.

Charring the outer layer of the wood makes it more resistant to insects and can make it incredibly beautiful. Fire hardening wood works especially well for fence posts because a layer of charcoal is formed that adds a protective layer against wood rot and decay.

Technique

The heat from fire or flame is what actually makes the wood harder, but you have to be careful when you’re using this technique. Too much fire, and you can actually burn the wood and make it weaker.

You can use a fire pit or a handheld torch like a Bernzomatic. You have much more control with a Bernzomatic, so that’s one of the methods I prefer to use for woodworking projects.

If you’re using a firepit, use firepit gloves and a pair of tongs so you don’t burn your hands. Turn the wood often to keep it from catching on fire.

Pros and Cons

The fire hardening method enhances the look of wood and can completely transform its appearance. Some people use this method just to improve the appearance of wood alone.

On the downside, hardening wood with fire requires a lot of patience, and you have to be careful about burning yourself.

Here’s a great video explaining how to use fire to harden wood!

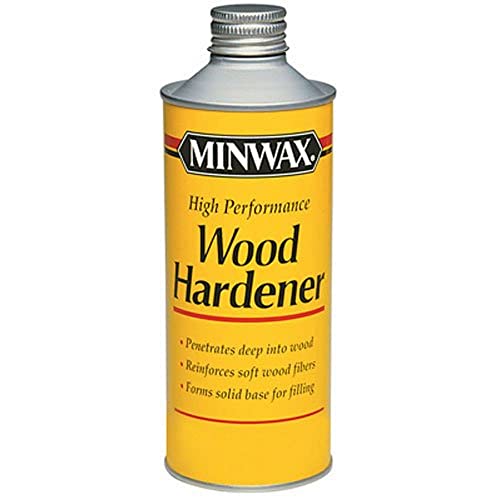

Method 2: Use Wood Hardener

Wood hardeners can be used to salvage old wood that has been damaged by decay and insects. There are many different brands, and some are thin, while others have a thicker consistency, making it easier to paint them on vertical wood.

You can also choose two-part epoxy wood hardeners, which are rated for structural use. They are more expensive, but they will bond to the wood and can even be used on support beams.

Technique

The best technique will depend on the type of project and the wood hardener product. One of the most popular wood hardeners is Minwax Wood Hardener, which is made to work with Minwax Performance Wood Filler – one of my favorite wood fillers you can buy.

- Is a quick drying liquid formulated to strengthen and reinforce decayed or rotting wood

- The hardener penetrates deep into the wood and its special resin binds and reinforces the decayed wood fibers

- High Performance Wood Hardener seals from further moisture penetration and hardens to a rock hard solid base…

Apply wood hardener by painting it on, and then let it dry. Then, mix the wood filler with the hardener, using a 16:1 hardener-to-filler ratio. After it dries, you can sand it and finish it however you choose. This is a great product for fixing decayed wood in fences, decks, and exterior siding.

Pros and Cons

You have to choose a wood hardener with the right consistency for your project. The thinner it is, the better it will penetrate into the wood. However, that can make it hard to apply, and it doesn’t offer the best structural support.

One of the nice things about wood hardener is that it can enhance the appearance of wood. After it dries, you can apply polyurethane with roller over it for maximum hardness and protection.

Method 3: Epoxy Resin

Epoxy resins are another great type of wood hardener that can be used. They offer superior strength, but they aren’t solvent-based, so they don’t penetrate wood as well as products like Minwax Wood Hardener. Epoxy resins are a great choice when you’re working on a large project so you can easily coat the entire wood surface.

Technique

To harden wood with epoxy resin, start with clean, dry wood. Epoxy creates an impermeable coating, so any moisture in your wood can get trapped, which will cause problems down the road.

If you’re using a single component epoxy, you can apply it straight from the container. With a two-part epoxy resin, you have to mix the two parts together, which takes a little bit of time but it’s pretty simple.

Use an old paintbrush to apply the epoxy resin, and apply a second layer after a few hours. Always read the instructions for whatever product you choose because they’re all a little different.

Pros and Cons

One of the best things about epoxy resin is that it can be used on almost any material, including concrete and plastic, so it’s perfect for a wide variety of projects.

Epoxy resin creates a strong, waterproof seal that will protect your wood from moisture, but it has a longer curing time than other wood hardening methods and you’ll want to wear the proper safety gear when using it.

Method 4: Wood Stabilizer

A wood stabilizer is another product you can use to harden wood. Stabilized wood is easier to turn and carve because it is less prone to cracking, and some pieces of wood that have a lot of spalling and unique grain textures aren’t good for turning unless they’re stabilized.

Technique

One of the best products for this stabilizing wood is Total Boat Penetrating Epoxy, which is low viscosity and easy to apply.

- WOOD HARDENER FOR ROTTED WOOD: two-part epoxy system seals, hardens, preserves, and protects all types of wood…

- PENETRATING WOOD SEALER: An ideal dry rot treatment; this marine-grade epoxy resin is perfect for wooden boat…

- CLEAR LOW VISCOSITY RESIN WITH MANY USES: Use on all softwoods, including cedar, cypress, fir, pine and…

The best way to stabilize wood is with a vacuum chamber. The vacuum pulls the wood stabilizer product into the wood, replacing the moisture and hardening the wood.

You don’t have to use a vacuum chamber with the penetrating epoxy, but you’ll get a better result. You can get an entire setup with a vacuum chamber and pump for less than $200, and it’s not hard to learn how to harden wood using one.

Some wood stabilizers are heat-activated, like Cactus Juice Stabilizing Solution. Some people even use an old toaster oven set to 220°F (104°C) for this purpose.

Pros and Cons

Wood naturally shrinks and expands, and wood stabilizers work to protect your projects from this process. They typically cost more than wood hardeners, and they have a longer curing time.

The main difference between a wood hardener and a wood stabilizer is that hardeners protect the wood from rot and decay, while stabilizers seal the wood and make it more stable.

Method 5: Polyurethane

One of the most common methods used for hardening wood is polyurethane. Most people use polyurethane to protect and preserve wood by coating and sealing it, but it will also harden wood and ensure a durable surface.

Polyurethane has a lot of different uses, and it enhances the appearance of wood while making it stronger and harder.

If you want something more natural, you could also consider a tung oil or linseed oil finish, but these won’t give you the same protection as polyurethane does.

Technique

Polyurethanes are easy to apply. You can roll it onto your wood with a paint roller, you can use a brush for polyurethane, or even use a polyurethane sprayer to apply this durable finish. Depending on the type of product you use, it will take a few hours to dry completely before you can apply a second coat.

You can use either water-based or oil-based polyurethane and there are advantages and disadvantages to each. If you’re using oil-based polyurethane, it’s important to wear a respirator because the fumes are unbearable.

Pros and Cons

Cleanup is a little harder with oil-based products, and it takes a little longer for them to dry. Oil-borne polyurethane dents more easily, while acrylic polyurethane scratches more easily.

Polyurethane isn’t the best product for some types of projects, like if you’re planning on turning wood or carving it, and it won’t increase the structural integrity like epoxy resins and wood hardeners will. But it makes your wood stronger, more durable, and less susceptible to decay and insects.

Method 6: Heat Gun and Oil Based Paint

Heat tempers wood and makes it harder, and one of the easiest ways to temper wood is with a heat gun. It’s also a handy method to use when you don’t have a fire pit or can’t start a fire in your backyard.

Technique

Adding a top coat of oil-based paint helps seal and harden wood, ensuring that it will last for many years.

You can also use other materials to seal the wood after treating it with a heat gun, including substances like pine resin pitch, beeswax, and Cactus Juice.

The technique you use to harden wood with a heat gun will depend on the look you’re trying to achieve and whether or not your wood has been treated. Be very careful using a heat gun on treated wood because the laminate can split or catch on fire.

As far as appearance, you can achieve several finishes on wood with a heat gun, from light charring to dark char. Select a clear oil-based top coat for an incredible look.

Pros and Cons

Heat guns are a great tool to have in your toolbox, but when you’re using one to harden wood, you should start out using the lowest setting. Be careful because they are hot enough to start wood on fire.

The best thing about using a heat gun vs. the fire hardening method is that you have a little more control, and since you can’t always start a fire in your backyard, you have more flexibility.

Benefits of Hardening Wood

So, why would you want to harden wood, and what benefits does it provide? Take a look at the reasons to harden wood for all sorts of woodworking projects.

Strength and Durability

Durability and strength are two different things when it comes to wood, but hardening wood makes it stronger and more durable.

Wood that has been hardened can provide greater structural support, and it can also hold up to wear and tear better. Hardened wood is less likely to get dented or scratched, for example.

Insect and Decay Resistance

Rotting and insect-damaged wood loses its structural integrity, but it can usually be repaired with wood hardening products. There are several products available that can be used for both interior and exterior applications.

If you have wood that has been damaged by termites or water damage, you can restore it with some of these amazing epoxy wood fillers like 3M’s Bondo Wood Filler or J-B Weld Wood Restore Liquid Hardener.

Are you wondering how hard wood can be? Check out the video below!

Brings Out the Natural Beauty

Hardening wood can bring out the natural beauty of the wood grain and enhance the rich tones of certain types of wood. The best method for enhancing the appearance of wood is treating it with heat and then applying some finish, but you can also achieve unique results by charring wood with fire.

Factors That Influence the Hardness of Wood

What makes some woods harder than others? While softwoods can be hardened, many of them will never have the same degree of hardness as woods like ironwood, maple, oak, hickory, or walnut.

Wood Type

Wood is classified into two types of hardness, including hardwood and softwood. Hardwoods are denser and heavier and used for things like hardwood floors, and softwoods are lighter and can be easier to work with and often used for framing and construction.

Hardwoods come from angiosperm or deciduous trees, like maple and oak. Softwoods typically come from conifers, like fir and pine wood.

Wood Grain

Wood grain is developed in wood as it grows because of the way the growth layers are formed. Some types of wood naturally have tight wood grain because they are slow-growing.

The straightness of wood grain helps determine how strong wood is, but it’s usually the tightness of grains that leads to the hardness of the wood.

Moisture Content

As the moisture content of wood is reduced, it gets harder. When it dries, the cells inside the wood collapse, which shrinks the wood and makes it harder.

Turning greenwood is a lot easier for this reason. It’s easier on your tools, and you won’t have to sharpen them as often because the wood is softer.

Age

Sometimes, wood hardens with age. It continues to dry as it ages, and by the time it’s been around in a dry building for several decades, it can get really hard.

However, wood isn’t always kept dry. Sometimes, when it’s exposed to insects or the elements, it weakens over time.

Final Thoughts on Hardening Wood

There are a lot of ways to harden wood, but some methods are better suited to certain types of woodworking projects.

To protect against rotting wood, consider using the polyurethane or epoxy methods. If you want a super easy way to make wood stronger, consider using a wood hardener.