How to Seal & Waterproof Particle Board (EASY Step by Step Guide)

Particle board has many distinct advantages as a building material, which is why it’s used in so many types of projects, from kitchen cabinets to floors, and more.

But unfortunately, particle board isn’t waterproof – which can cause some problems.

I’ve used particle board in a lot of different ways, including places where I needed it to be sealed. In this project guide, I’ll explain how to seal particle board to ensure your projects resist water damage. Let’s dig in!

- Sealing particle board is a great way to make your wood more durable and water resistant.

- To seal particle board, you’ll need to purchase a sealant and simply apply it across the surface of your wood. Depending on how much protection you desire, you may want to apply multiple coats.

How to Waterproof Particle Board

Particle board isn’t just an alternative to plywood. It has distinct advantages of its own as a building material, like being less likely to warp and having better dimensional stability. It’s not prone to movement like timber is, and it’s also much less expensive than plywood. Sounds amazing, right?

Sealing particle boards will make them more durable and less susceptible to water damage, and it’s a great way to protect furniture, flooring, and walls that are made with this material.

I used particle board to make my kitchen island from two base cabinets. My kitchen island came out great because particle board is so easy to work with, but I was slightly worried about moisture, so I sealed the particle board cabinets.

Sealing particle board is easy. I’ll explain how to do it in a few easy steps. Let’s get started!

Step 1: Tools and Materials

As with any project, gathering your tools and materials before you start will help your project go more smoothly. I like to have everything I need at my fingertips and highly recommend you do the same.

I also like to prepare a work area. Particle board sheets are large, and they can be a little unwieldy for one person to handle. I find it easier to make my cuts first and then seal the pieces I use in my project afterwards.

Either way, find a place where rain won’t be a problem and set up a couple of sawhorses to lay the particle board across. If you’re using particle board for flooring, you can screw and glue it, then apply the sealant directly to the floor.

Tools You Need to Waterproof Particle Board

Here is a list of tools you’ll need to waterproof particle board and begin the sealing process:

- Sealant

- Sandpaper

- Sanding block

- Orbital sander

- Paint roller

- Paintbrush

- Paint tray

- Paint sprayer

Depending on the method you use to apply the sealant, you may not need all these items.

Safety Precautions

Sealing particle board isn’t the most dangerous project in the woodworking world, but you should still take a few safety precautions.

Wear a dust mask or respirator, especially when applying an oil based polyurethane sealer. The fumes can be really toxic. You should also use a respirator and goggles if you spray the sealant because the tiny particles can get in your lungs and do a lot of damage.

No matter what type of sealant you use, you should always work in a well-ventilated area when you’re particle board sealing. Open the windows and set up some box fans to get some airflow.

Step 2: Prepare the Particle Board

Once you have your work area and tools ready, it’s time to prepare the particle board before you seal it by cleaning, sanding, and cutting.

Clean

I highly recommend you vacuum the particle board and then sand it. After you’re done sanding and cutting, wipe it down again to ensure it’s clean.

Even after you sand and vacuum the particle board, it might look clean, but it will have a fine layer of dust on it. You can use a few different methods to clean the particle board, but avoid using too much water, which will damage the particle board.

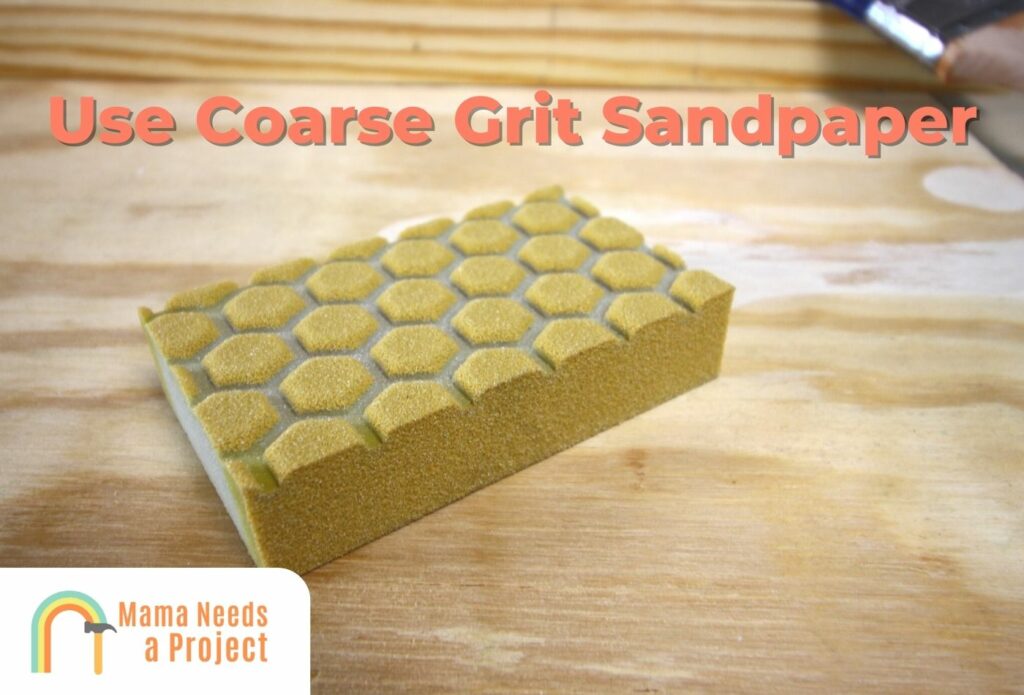

Sand

Before you sand, make sure the surface is completely dry. The surface of the particle board is actually very smooth, but using 120-grit sandpaper will create a better surface for the adhesion of the sealant.

An orbital sander is the best tool for this job. It makes sanding easy, and you don’t have to worry about the grain. You only need to sand enough to scuff the surface.

Always wear a dust mask when you’re sanding particle board. Particle board is held together with glue, and you don’t want the small wood and glue particles getting in your lungs.

Cut

Using a table saw or circular saw, cut the particle board to the dimensions required for your project.

This makes them easier to work with when you start applying the sealant. It also allows you to seal the cut edges and helps prevent moisture from entering the particle board.

The final preparation step is to clean the particle board surface to remove any sawdust particles. Make a cleaning solution with one part vinegar and one part water, then use a slightly damp rag to wipe the surface of the particle board and remove any dust particles.

You can also use 1 part bleach to 3 parts water. Both of these solutions will help disinfect the particle board to prevent problems like mildew.

Step 3: Apply the Sealant

Depending on what type of sealant you’re using, it can be applied in different ways.

- Brush– A paintbrush is one of the easiest methods to apply all types of sealants, including epoxy resin coatings. You can use a synthetic paint brush, and apply the sealant in even strokes, making sure you get all of the edges. Check out these amazing brushes for sealants.

- Roller– A nap roller made from synthetic fibers is another effective way to apply sealant to particle boards, and it’s much quicker than using a paintbrush.

- Paint sprayer– You can use a paint sprayer to apply water based sealants. If you’re using an oil based poly, you will need to use a thinner.

- Spray sealant– Many types of sealants, including lacquers, shellacs, and Gorilla Waterproof Patch & Seal Spray, are available in aerosol cans. They are perfect for small to medium-sized projects because they go on easily and smoothly.

Step 4: Sand and Recoat

Unless you’re using an epoxy resin, which only requires one coat, you should sand the particle board and apply another coat. I recommend at least three coats of sealants to provide maximum protection but you can do more or less depending on your project.

Best Sealants for Waterproofing Particle Board

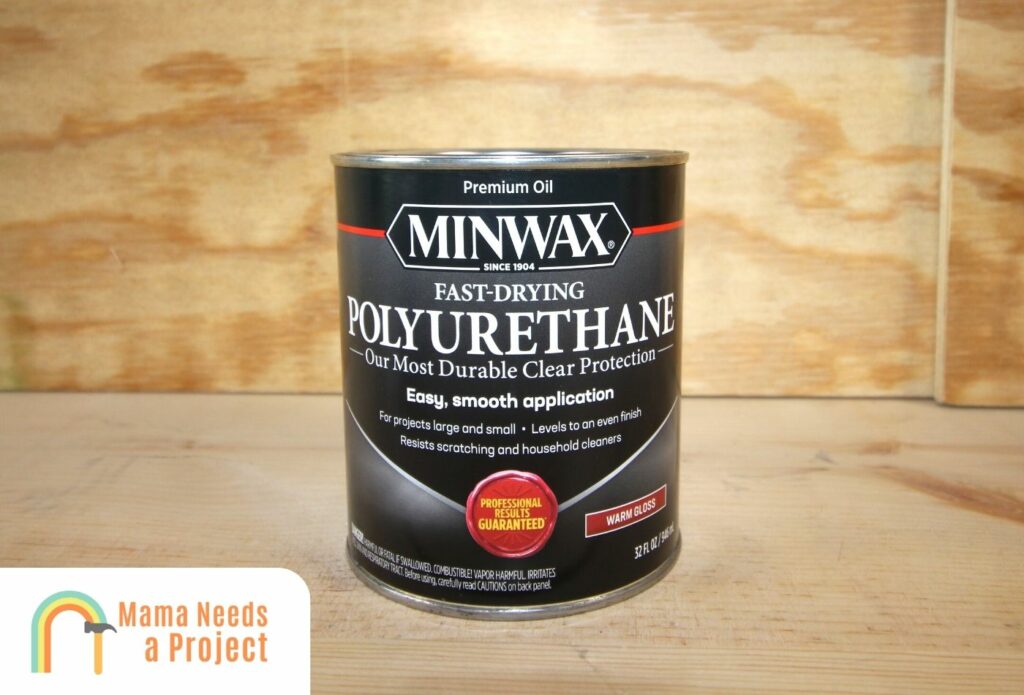

What is the best sealant for sealing particle board? Oil based polyurethane is one of my favorite sealers because it won’t add moisture to the particle board, which can lead to swelling.

However, many people prefer to work with water based polyurethanes because cleanup is easier and there are less fumes, and some people prefer epoxy resins because they are much more durable than other sealants.

Learn more about the various types of sealants used to waterproof particle board. I’ll also offer some tips and tricks for applying each type.

Oil Based Polyurethane

Oil based polyurethane is a top-notch particle board sealer. Because particle board is highly absorbent, some people don’t like to use water based sealants, which soak into the wood. When you choose an oil based polyurethane, you don’t have to worry about the moisture in the sealant.

When using oil based poly, allow for more drying time. It can take up to 24 hours for oil based polyurethane to dry completely, depending on the temperature and humidity. At the very least, it’s a good idea to let it dry overnight.

You can use a brush or roller to apply thin coats. Thinner coats of polyurethane are more likely to dry thoroughly.

One of the benefits of oil based polyurethane is that it will make the particle board more durable. If you need more strength, you can laminate two pieces together and then seal them as one piece.

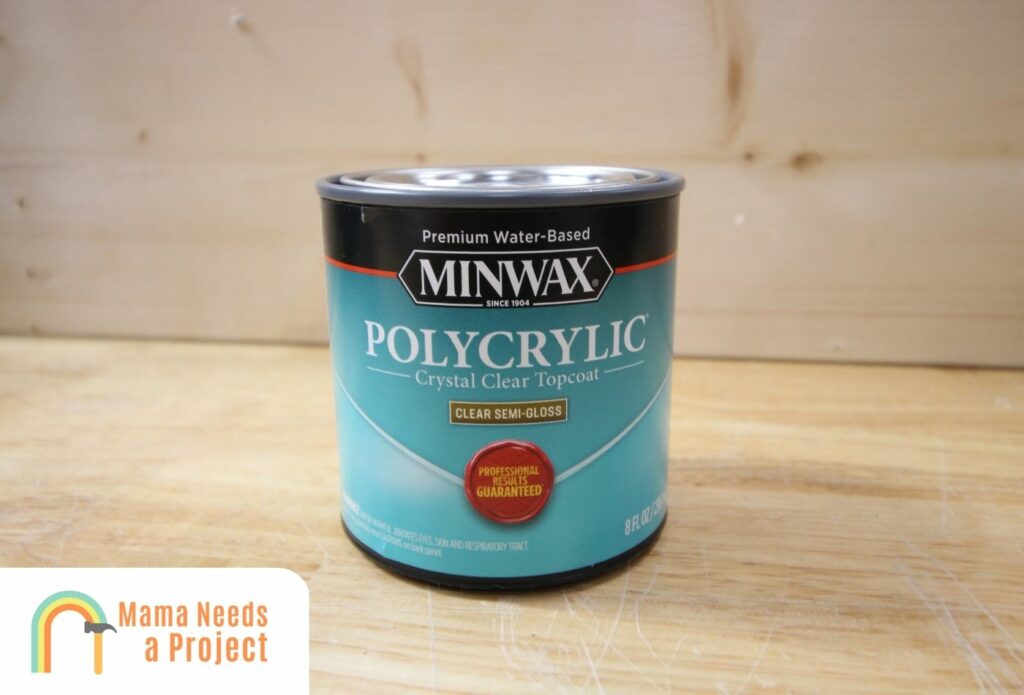

Water Based Polyurethane

Water based polyurethane is a clear acrylic sealant that can be used as a particle board sealer.

It’s easier to use than oil based poly. It’s easier to clean, doesn’t smell as bad, and dries faster, which can make your project go a lot faster.

However, one problem with using water borne sealants on particle board is that they are highly absorbent, and the moisture in the sealant can cause the particle board to swell. One way to combat this is to apply a very thin layer and let it dry completely before applying another.

Both water based and oil based polyurethane last about 10 years, as long as you use a high quality product. Inferior water based poly sealants only last a few years, so I like to spend the extra money and get the best product possible.

My top recommendation for a clear acrylic sealant is Minwax Polycrylic. It’s easy to brush on or spray on with a paint sprayer.

- PROTECT WOOD SURFACES – Minwax Polycrylic Protective Finish protects and adds beauty to your interior wood…

- CRYSTAL CLEAR FINISH THAT LASTS – The crystal clear finished offered in this protective coating is ideal for…

- SATIN SHEEN – Give your wood projects a sleek finish with a satin clear varnish. It not only protects the…

Epoxy Resin

Epoxy resin coatings will bond to almost any surface, including metals, plastics, concrete, and wood, and they make excellent particle board sealers.

People use epoxy resins to make countertops and tables because they dry clear and provide the best protection. Epoxy has a lot of different uses, and it can be used over the top of particle board to make it stronger and more durable.

Choose between 1 part epoxy coatings, which can be applied right out of the can, or 2 part epoxy coatings that must be mixed together.

Epoxy is a great waterproof sealant, but it can take a while to dry.

Why You Should Seal Particle Board

Whether you’re using particle board flooring or you’re using it for shelving, there are several benefits of sealing particle board.

Protection from Moisture Damage

Whether you’re protecting particle board against damage that’s already occurred or trying to prevent future water damage, sealing it is an excellent solution.

Particle board can swell due to changes in the humidity level and when exposed to moisture. In extreme cases of water damage, wet particle board can disintegrate unless it’s protected with a sealant.

Most people try to avoid using particle board in areas where there’s a lot of moisture, but once it’s been properly sealed with a high quality sealant, it’s protected by an impermeable layer that makes it water resistant. In some cases, you can make particle board completely waterproof making it a more useful wood alternative.

Increased Strength and Durability

All types of wood can be hardened in various ways to make them stronger and more durable, which is one of the main reasons to seal particle boards.

Particle board isn’t as strong as plywood and tends to warp over time under certain conditions. Waterproofing particle boards can make them hard and will help keep them from sagging.

If you’re using particle board in a place it can get wet, or if you have long shelves that could get overloaded, it’s a good idea to use a sealant. The stronger the sealant, the more durable the particle board will be.

Easier to Clean and Maintain

Unless it’s sealed, particle board can be hard to clean. If you’re using it anywhere in your kitchen, it will be prone to getting stained from spills and grease splatter.

Since you don’t want to wet particle board that hasn’t been sealed, it can be hard to clean. No matter where you use particle board, if you want to be able to keep it clean, you have to seal it so you can wipe it down.

Improved Appearance

I already touched on how epoxy is used to enhance the appearance of all types of countertops and tables. You can use any sealant to improve the appearance of particle board, including water and oil based poly.

You can enhance the appearance of particle boards in various ways, either by painting, staining, or tinting polyurethane. If you plan to stain particle board, you should seal it first and then use a gel stain. Otherwise, it will absorb too much stain, which can compromise the integrity of the wood and staining will be blotchy.

Cost to Seal Particle Board

So, how much does it cost to seal particle board, and is it really worth it?

The cost to seal particle board depends on the type of sealant you use, how big your project is, and whether or not you have to buy tools and safety supplies. In most cases, it should cost under $50 or $100 to seal particle board.

- Varathane Oil based polyurethane – 1 quart- $17.00

- Varathane Water based polyurethane– 1 quart- $25.00

- Gorilla Waterproof Patch & Seal Spray- 14 ounces- $15.00

- Epoxy Resin Glaze Coat- 1 quart- $25.00

One quart of polyurethane covers about 125 square feet, but remember that you need to apply up to 3 coats. One quart of epoxy will cover up to 6.4 square feet, but one coat is more than adequate.

I think it’s worth the extra cost in many cases because of the benefits that it provides. The truth of the matter is that particle board and plywood are sometimes used in place of each other, but they are completely different types of building materials. Sometimes, particle board is the best material to use, but it needs to be sealed.

Final Thoughts

Waterproofing particle board is a great way to take advantage of the amazing features of this versatile wood without having to worry about the downsides.

By applying a waterproof sealer, your particle board projects can last for years.