5 Types of Wood Glue: Which is Best? (Ultimate Guide)

These days, there are many types of wood glue available, and as a woodworker you should know what the main wood glues are and how they’re different from one another so you can choose the best one for your project.

Ready to learn the different types of wood glue? Let’s dig in!

Some of the most commonly used wood glues are:

- PVA glue (Titebond, Elmer’s)

- Polyurethane glue (Gorilla)

- Epoxy glue

- Cyanoacrylate glue

- Hide glue

Polyurethane, epoxy, and cyanoacrylate wood glues are stronger than PVA and hide glues, but PVA and hide glue are more affordable, versatile, and most commonly used.

PVA Wood Glue

The white and yellow glues that most people use are polyvinyl acetate, or PVA glue.

Otherwise known as wood glue, carpenter’s glue, school glue, and white glue, PVA glue was discovered in 1912 by a German doctor named Fritz Klatte. Today, it’s arguably the most widely used adhesive, as it’s strong and generally non-toxic.

In addition to being strong and safe, PVA glue is also affordable, easy to clean up, water-resistant, flexible, heat-resistant, sandable, and versatile, as it can be used both indoors and outdoors to great effect.

Despite being water-based, PVA glue is incredibly strong, being able to withstand between 3,600 to 4,000 PSI. It may be hard to believe, but a wood glue bond is stronger than most woods, even many dense hardwoods.

PVA wood glue is usually applied with either a wood glue dispenser or a wood glue brush. If you have neither, you could use your finger, but this will make for a messy and imprecise application.

Any excess glue should be wiped away with a wet rag immediately, for the longer it’s left to dry, the harder it’ll be to remove.

Some popular PVA glues are Gorilla Wood Glue, Titebond Original, Titebond 2 Premium, and Titebond 3 Ultimate. Of these four glues, only Titebond 3 Ultimate is certified waterproof.

Most PVA glues become semi-dry in 10 to 15 minutes, but the more viscous ones take 20 to 30 minutes to become semi-dry.

No matter what kind of wood glue you use, it’s best to give it at least 24 hours to cure, as waiting ensures the bond reaches its maximum strength. It’s best to apply PVA glue when it’s 50°F to 55°F.

Worried about what color your glue will dry? Check out my guide on what color each wood glue dries!

Best Used For

- Woodworking: Because it’s easy to use, cheap, easy to clean up, and strong, PVA glue is a best friend to woodworkers who specialize in small projects. But for larger woodworking projects, it’s best to go with a stronger glue.

- Arts & Crafts: We’ve all used white or yellow glue for arts and crafts before, and no glue is more associated with arts and crafts than PVA glue.

- Bookbinding: PVA glue has long been used for bookbinding, and today there are special PVA glues just for this. You could also use PVA wood glues for bookbinding, but in truth this would be a little overkill, as most books don’t require that much glue strength.

Polyurethane Wood Glue

Polyurethane glue, otherwise known as PA adhesive, is a synthetic plastic resin that’s used to bond different materials together.

Polyurethane wood glue is sometimes called Gorilla Glue, mainly because the Gorilla Glue Company has been manufacturing this wood adhesive longer than anybody.

Unlike other glues, moisture actually helps polyurethane adhesive cure, which means applying it in a humid environment is likely to yield desired results.

Additionally, polyurethane glues expand as they dry, which is one reason why they’re used for joinery; they fill joint gaps well and can be sanded once dry.

But polyurethane glue’s tendency to expand as it hardens can be a negative, like when it pushes two joined materials apart. For this reason, you must use clamps after applying polyurethane glue to ensure a very strong bond.

Polyurethane wood glue works well with oily woods, which is something PVA wood glue can’t boast, as the latter glue is water-based and therefore unable to mix well with oily wood.

Polyurethane glue can become semi-dry in under 30 minutes (with clamping), and a temperature above 55°F, along with decent humidity, are ideal drying conditions.

But polyurethane glues do have their drawbacks. For one, these glues are more toxic, containing more VOCs than most other wood glues.

It’s more expensive too, and it’s hard to remove; to do so you’ll need a chisel, mineral spirits, and sandpaper.

Best Used For

- Gluing End Grain: The end grains of a board are the sides that show exposed wood fibers. Gluing two end grains together is challenging with most wood adhesives, but not polyurethane wood glue. Unlike other glues, polyurethane glue gets absorbed into the wood’s pores, and this is where its bonding strength comes from.

- Outdoor Projects: Polyurethane glue’s strength makes it ideal for a range of outdoor and indoor projects, but it’s outdoors where this glue really shines. It can withstand sudden fluctuations in both temperature and humidity, and it can hold up against the elements, in large part because it’s heat-, corrosion-, and water-resistant.

Epoxy Glue

Epoxy glue is another kind of wood glue that’s sought-after because of its strength. Specifically, this glue can withstand 5,000 to 10,000 psi, and it becomes a waterproof glue as it cures.

While some manufacturers claim their epoxy glues can dry in just a few hours, it’s best to give epoxy glue a day or two to cure before working with it.

This glue is also waterproof, meaning it’s great for outdoor projects.

Plus, it takes finish well, and it can blend into wooden surfaces better than most wood glues.

But this kind of wood glue is one of the most expensive, which means you should apply it sparingly.

Also, it doesn’t work all that well with acidic and moist woods, so keep it away from Douglas fir and African Blackwood.

Check out my epoxy glue vs wood glue comparison to decide which is better for your project!

Best Used For

- Joinery: Epoxy wood glue is great for filling the cracks and gaps that are sometimes made when you join two pieces of wood together. All you have to do is mix the epoxy with some sawdust and then apply this mixture to the gaps. After the epoxy dries, it can be sanded and finished. Applying epoxy this way will also make the joint stronger.

- Making & Repairing Wooden Furniture: Epoxy wood glue is also used to construct and repair a wide range of wooden furniture. Epoxy wood glue is used over other types of wood glue because it’s easy to finish and it’s strong. Other wood glues are easy to notice and take away from the overall visual appeal of a piece.

Cyanoacrylate Glue

Cyanoacrylate glue, otherwise known as CA glue, super glue, and Krazy Glue, is a quick-drying wood glue that’s acrylic-based.

It can form a strong chemical bond like other wood glues, but it’s different in some important ways.

For one, it dries much faster than other glues, and the drying process can be expedited if you use an accelerator spray. Simply spray the parts of the wood that don’t have CA glue and then press the pieces together until a bond forms; you can use clamps but these aren’t necessary.

CA glue comes in a range of viscosities, so some are thin like water while others are thick like an oil-based substance.

This kind of glue can withstand 4,000 psi, and working with it is a lot less messy than working with two-part epoxy-based glue. It’s non-toxic too, and it’s an affordable option.

But CA glue is prone to peeling and it doesn’t resist temperature fluctuations or corrosion well.

Plus, it’s not the strongest joint filler, and it can become brittle if applied improperly to joint gaps.

Best Used For

- Extra Support: CA glue can be used to lock wood pieces in place. First, you’d apply the glue and spray it with the accelerant to fix the pieces together. Then you’d apply CA glue around the perimeter of the raised piece for extra support.

- Clamp Substitute: Don’t have clamps that are suitable for holding two pieces of delicate wood together? You can use CA glue in place of clamps. First, apply some standard white glue, but leave some space for the CA glue. Next, spray the material you’ll be fixing the wood to with accelerant, and then press the glued wood into the material.

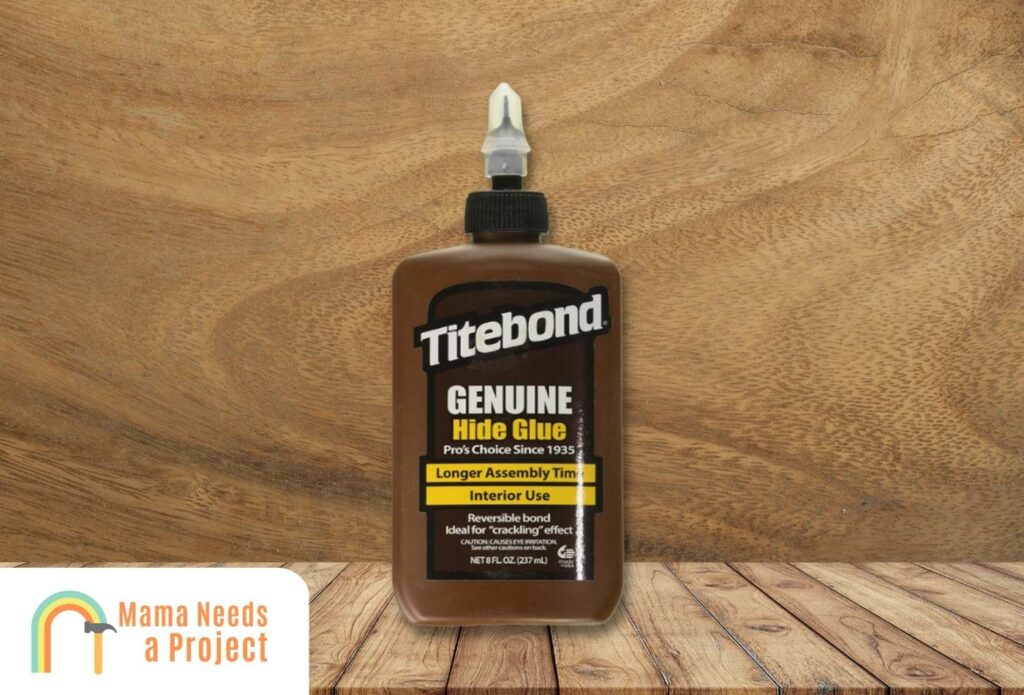

Hide Glue

Hide glue has been around for a very long time, and it used to be the go-to glue for practically all woodworkers.

It can withstand 3,000 to 5,000 psi, and it doesn’t contain any VOCs.

Plus, the bond it forms can be heated and broken down, which is something you can’t do with any of the other glues discussed thus far.

But applying it is not easy, it doesn’t last a long time, and it’s not that water resistant.

Check out my hide glue vs wood glue comparison to decide which is better for your project!

Best Used For

When PVA glues and other types of wood glue aren’t available, you can make do with hide glue.

Hide glue is also ideal if you’re only looking to make temporary glue bonds.

Final Thoughts

In the end, there are several types of wood glue, and the project you’re working on will in large part determine which glue is necessary.

If you want a strong glue, go with polyurethane or epoxy. If you want an affordable glue, stick with classic PVA. Don’t want to wait forever for glue to dry? Go with CA glue.

Once you’ve used all of these glues, you’ll know which projects call for specific wood glues and which don’t.