How to Tell if Wood is Pressure Treated (8 EASY Ways)

Pressure treated wood is a great option for outdoor projects that require superior strength and weather resistance. But how do you tell if wood is pressure treated?

I’ll show you several easy ways to identify pressure treated lumber so you can get on with your projects.

The best way to tell if wood is pressure treated is by looking at the color, weight, smell and tag on the wood. Darker wood or wood that is heavier are two key indicators that wood is pressure treated.

8 Ways to Tell if Wood Is Pressure-Treated

1. Color

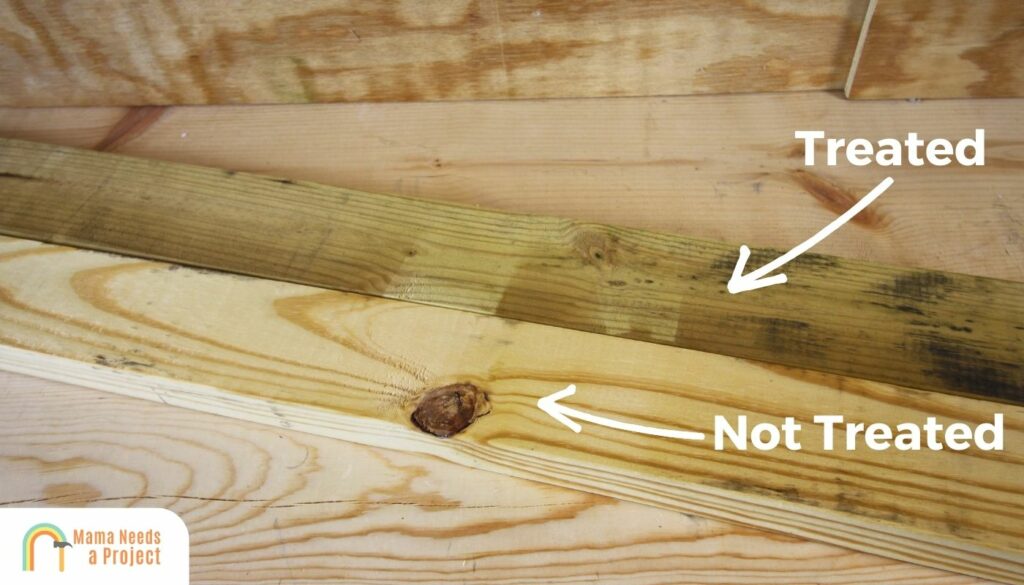

Pressure-treated wood varies in tint based on the preservatives used.

For example, when softwood (pine, fir, spruce, etc.) is pressure-treated, it is often turned dark brown by the chemicals used.

Even if a piece of wood has the color that pressure-treated wood usually has, it’s best to run another test to confirm that it is in fact pressure-treated.

It’s also important to remember that as wood gets older it tends to discolor, and you could easily mistake an old piece of wood for something pressure-treated if you’re going off color alone.

2. Smell

Pressure-treated wood also has a distinct smell that should be easy to identify.

It has a chemical smell that’s pretty easy to identify, as it’s treated with various chemicals for strength. Even water-based preservatives have a distinct smell, albeit slight. Oil-based preservatives, on the other hand, will give off an oily smell, and this wood may be slick.

Regardless of what wood has been treated with, it’s not going to have that natural wood smell after it’s been treated. So if you have spruce or pine board—both of which are naturally fragrant—and you don’t smell anything but chemicals, it’s almost certain the wood has been pressure-treated.

3. Weight

Pressure treated lumber will weigh more than non treated wood because of all the chemical components added during the treating process.

By comparing one piece of lumber to another – you should be able to spot which one has been treated because it will weigh significantly more.

4. Size

Pressure-treated lumber is usually larger than natural lumber because the addition of preservatives makes pressure-treated wood swell. The size difference is slight, but it’s enough that you should be able to tell.

You should also give the wood adequate time to dry before building with it, as if it’s still swollen during construction, it’ll shrink later on and possibly affect the shape, size, or soundness of your structure.

5. Incisions

Some woods require incisions in order to become pressure-treated.

The incisions can be anywhere from a 1/2 inch to 2 inches in length spread in regular intervals throughout the wood. Hardwoods like oak or maple wood usually require incisions because the preservatives can’t penetrate the wood on their own.

Remember, incisions don’t always mean the wood is pressure-treated. Some pieces of old wood may have similar incisions from previous work done on it.

6. Tag/Stamp

After wood has been pressure-treated, it’s tagged or stamped with a list that includes all the chemicals used to treat the wood.

The tag/stamp is usually near the end of a board. It lists the preservatives used and explains how they were applied. Common preservatives include:

- Acid copper chromate (ACC)

- Alkaline copper quaternary (ACQ)

- Copper azole (CA)

- Copper-HDO

- Pentachlorophenol (PCP)

- Sodium Borate (SBX)

- Micronized Copper Quaternary (MCQ)

7. Test Kit

You can also purchase a test kit to determine whether or not wood has been pressure-treated.

That said, a test kit won’t reveal what exactly has been used to treat the wood, unless chromated copper arsenate (CCA) is detected.

Up until 2004, this chemical was used widely by manufacturers to pressure-treat wood, but after the dangers of using it came to light, it was phased out and substituted with safer preservatives.

8. Fact Sheet

If you’re getting pressure-treated wood from a big box hardware store or lumber mill, you should be able to get a consumer information sheet with your purchase.

This sheet will provide more detail than the tag/stamp discussed earlier is mandated by the EPA so you can know exactly which chemicals have been used on your wood.

If you’re unsure of whether or not a piece of wood has been pressure-treated, the consumer information sheet will provide a clear answer.

What is Pressure Treated Lumber?

For wood to become “pressure-treated”, it must go through a multi-step process that involves heavy machinery and high-tech computers.

Essentially, special preservatives are forced into the wood by way of pressure that strengthen the wood and make it long-lasting.

Afterward, pressure-treated wood usually goes through another process so it’s flame-retardant.

Nowadays, pressure-treated wood is used to construct a variety of structures because of its added strength and durability.

Because of its strength and lifespan, pressure treated lumber is usually more expensive than its natural wood counterparts.

Did you know you can treat wood yourself? Check out these ways to treat wood for outdoor use

Pros and Cons of Using Pressure-Treated Lumber

Durability

Pressure-treated wood’s durability is the main quality that makes it so sought-after.

It can resist dents and scratches far better than untreated wood, and it takes ages to be worn down by the elements.

It’s also stronger, so it can support more weight.

Because of its unmatched durability, pressure-treated wood is used for both commercial and residential buildings and projects.

In many instances where natural hardwood would not be sufficient, pressure-treated does well—think decks, docks, porches, sheds, etc. It’s even more durable if you stain pressure treated wood.

Versatility

While using pressure-treated wood in its natural state is certainly possible, usually it’s stained or painted. Because of the sheer number of colors you can find, it’s more versatile than other materials like stone and vinyl.

Just make sure you stick to using interior wood inside and exterior wood outside, as exterior hardwood looks odd indoors while interior hardwood won’t hold up long against the elements.

Affordability

Pressure-treated wood is affordable in two ways.

First, certain kinds of pressure-treated wood are cheaper than many natural hardwoods like cedar and redwood.

Second, since you don’t have to replace pressure-treated wood often, it delivers a much higher return on investment (ROI).

That being said, when you compare many kinds of pressure-treated wood to their natural wood counterparts, you’ll find that pressure-treated woods are generally more expensive, but the difference isn’t all that much in some cases.

In the end, if you’re determining value based on how long the wood will last, pressure-treated wood is far more affordable than natural wood (which may have to be replaced often).

Ease of Repair

Not only is pressure treated lumber more durable, it’s both easy and inexpensive to repair or replace making it a great choice for many projects.

Natural

Although “natural” isn’t the first word you might associate with a piece of wood that’s loaded with chemicals, it is natural in the sense that it looks and feels like natural wood – especially if it’s been painted or stained.

Therefore, if you want the look and feel of natural wood with added strength and protection, choosing pressure-treated wood is a no-brainer.

If you plan to stain your wood, be sure not to stain pressure treated wood too soon or you may run into issues!

What Color Is Pressure-Treated Wood?

Chromated Arsenicals

CCA turns wood green. Therefore, if you find a piece of pressure-treated wood that has a green tint, stay clear—this wood could be dangerous if it’s loaded with CCA.

Copper Azole

Copper azole will turn a piece of wood light drown, and this chemical is considered a safer alternative to CCA. Wood that’s been treated with this chemical will become silvery-gray over time.

Alkaline Copper Quaternary

Wood that’s been treated with ACQ will turn tan or olive, and it’ll stay this color unless it’s painted or stained. The olive color ACQ produces doesn’t look anything like the color CCA turns wood, so you don’t have to worry about confusing the two. ACQ is relatively safe, and there are four kinds of ACQ pressure-treated wood: A, B, C, D.

Borate

Borate is used when other preservatives aren’t able to penetrate a hardwood. Borate diffuses once it’s penetrated the wood, whereas other chemicals would bond to the wood fibers. It’s a preferred option in residential foundation construction because it’s non-toxic and it doesn’t change the wood’s color.

Oil-Based Preservatives

Oil-based preservatives will either darken or lighten the wood. For example, creosote will turn it dark brown, pentachlorophenol will turn it light brown, and copper naphthenate can turn it dark green.

How to Tell if Wood Is Treated for Burning

Just like pressure-treated wood, flame-retardant wood is supposed to be properly labeled so the you know how strong it is, what chemicals were used to treat it, etc.

When reading a label, one metric you should look out for is “Flame Spread“. This number indicates how combustible wood is on a scale from 0 to 100.

According to the International Building Code, pressure-treated wood must have a Class-A flame spread rating, i.e. a rating below 25.

The amount of smoke created when the wood burns is also measured by a 0-100 scale, where a lower rating means the wood doesn’t emit as much smoke when burned.

FAQs

What color is pressure treated wood?

Pressure treated wood will usually have a slight dark brown or green tint that’s pretty easily identifiable when looking at it.

How can you tell if wood is pressure treated without a tag?

If wood doesn’t have a tag, you can usually tell based on the color, weight, and smell of the wood. If the wood is extremely heavy, or has a unique tint, or has a chemical like smell – the chances are that it’s pressure treated.

Final Thoughts

There are several ways to tell if lumber is pressure treated or not. Looking at the color, smell, size, incisions, and the end tag are all easy ways to determine if lumber has been treated.

The tag is the easiest way to spot pressure treatment, but looking at the color and weight of the wood can also be key indicators.